8

WWW.FUHR.DE

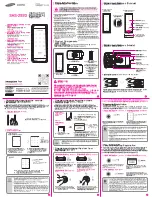

Door lock identification marking

PLEASE NOTE! It is imperative to note the following!

CE conformity in accordance with DIN EN 1125 and/or DIN EN 179 is only given, if the FUHR anti panic locks 833P and 834P

are used in conjunction with the tested and certified components. Please refer to our website

www.fuhr.de

for deatailed

information. Accessories such as soft latches, rolling latches or reduced latches are only permissible with emergency exit

hardware in accordance with EN 179.

Panic exit locking systems EN 1125 + emergency exit locking systems EN 179

Panic exit hardware EN 1125 and emergency exit hardware EN 179

autotronic

834P – type 4

autosafe

833P – type 4

1309 CPD 0110

2010

EN1125:2008

3|7|6|0|1|3|2|1|A/B|B

1309 CPD 0119

2010

EN179:2008

3|7|6|0|1|3|5|1/2|A/B|B/D

autotronic

834P – type 4 – double-leafed

autosafe

833P – type 4 – double-leafed

1309 CPD 0131

2010

EN1125:2008

3|7|6|0|1|3|2|1/2|A/B|A

1309 CPD 0132

2010

EN179:2008

3|7|6|0|1|3|5|2|A|A

Montagehinweise /

Installation instructions

Maintenance instruction

It is necessary to point out to builders and users that safety-relevant hardware components – depending on their frequency

of use – are to be checked for wear and tear and if they are mechanically secured at least once a month, but after approx.

20.000 cycles of operation at the latest. At the same time the panic/emergency opening function is to be checked.

Depending on the requirements, fixing screws must be tightened or the damaged or worn parts exchanged for original parts

by a specialised company.

Furthermore it is necessary to point out to builders and users that the following service work is to be carried out simul-

taneously:

• All movable parts and locking points must be lubricated and their function must be checked; using a force gauge, measure

and record the operating forces to release the exit device.

• Ensure that the keepers are free from obstruction.

• Check that no additional locking devices have been added to the door since its original installation.

• Check periodically that all components of the system are still correct in accordance with the list of approved components

originally supplied with the system.

• Check periodically that the operating element is correctly tightened and, using a force gauge, measure the operating forces

to release the exit device. Check that the operating forces have not changed significantly from the operating forces recorded

when originally installed.

• Only cleaning and maintenance agents, which do not damage the corrosion protection of the hardware components, are

to be used.

• We recommend you consider a service and maintenance contract with an authorised specialist company.