CAP-600

3

START-UP PROCEDURES

OIL RECOMMENDATION

Use Genuine

CURTIS

L

UBE

P

LUS Lubricants.

Specially

formulated for Curtis Reciprocating Air Compressors. Non-

Detergent type with anti-foam, anti-rust and oxidation inhibitors.

Recommended

ISO68 RC-1000

Premium Reciprocating

Compressor Lubricant,

Part no. VO411-3

, 12-quart case or

VO411-2, 4 gallon case.

Recommended

ISO100 RC-1000A

Premium Reciprocating

Compressor Lubricant

Part no. VO421-3

, 12-quart case or

VO421-2, 4 gallon case.

CURTIS

L

UBE

P

LUS Lubricants are available through your

authorized Curtis distributor.

If the compressor is equipped with an automatic start-stop

control (with pressure switch unloading), it is automatically

unloaded upon starting, and will automatically load after

attaining running speed. If the compressor is equipped with

a constant speed control (pilot valve unloading), it is

necessary to manually unload the compressor, if there is

pressure in the discharge line, in order to achieve an

unloaded start. The compressor must be manually loaded

after the compressor has attained full running speed, there

after, it functions automatically to maintain operating

pressure until the unit is shut off.

Close the disconnect switch and start the compressor.

Observe the direction of rotation, which should be

counterclockwise when viewed from the flywheel side of the

compressor on all models. For single-phase units, the

direction of rotation is determined by the motor nameplate

instructions, and is adjusted at the factory. For three-phase

units, if the rotation is incorrect, stop the unit and

interchange any two of the three wires to the motor at the

disconnect switch. This will reverse the direction of rotation

of the motor and compressor.

PREVENTIVE MAINTENANCE

A good maintenance program will add years of service to your air

compressor. The following is recommended as a minimum

maintenance program. (TURN OFF POWER BEFORE

SERVICING.)

LUBRICATION

1. For proper lubrication the compressor shall not be

operated below the minimum or above the maximum R. P.M.

recommended for the various models.

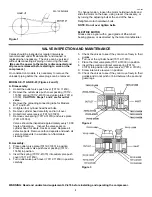

2. Maintain oil level mid-way between the upper and lower lines

of the crankcase sight gage.

NOTE ILLUSTRATION:

3. Stop compressor to add and gauge oil.

4. Do not fill above the upper line and do not operate compressor

with oil level below the lower line.

DO NOT OVER FILL

5. Change oil at the first 100 hours of operation and 1000 hours

thereafter, or as required. It may be necessary to change oil

more frequent due to abnormal humid and contaminated

conditions.

DAILY

MAINTENANCE

1. Check and maintain oil level at centerline of sight glass and

add oil as necessary.

2. Drain condensate from receiver unless it is equipped with an

automatic tank drain, in which case the drain should be

checked weekly to see that it is operating. See automatic tank

drain instructions.

3. Check for unusual noise or vibration (See "Trouble Shooting".)

WEEKLY MAINTENANCE

1. Clean the air filters. A clogged air filter can seriously affect the

efficiency of the compressor and cause overheating and oil

usage.

2. Clean all external parts of the compressor and driver. Be sure

to clean the intercooler-finned surface on two-stage

compressors. A dirty compressor will cause abnormally high

discharge temperature and resulting oil carbonization on

internal valve components

3. Check the safety valve manually (by pulling ring or lever) to

see that it is not stuck.

MONTHLY MAINTENANCE

1. Inspect the entire air system for leaks.

2. lnspect condition of oil and change if necessary.

3. Check drive belt tension and tighten if needed.

EVERY 3 MOS. OR 1,000 HRS. OF OPERATION

1. Change oil.

2. lnspect valves. Clean the carbon from valves and head if

necessary.

3. Check and tighten if necessary all bolts, nuts, etc.

4. Check unloader operation.

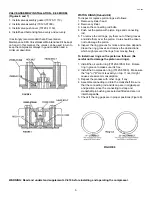

*CHECKING BELT TENSION

The v-belt(s) should be adjusted so that a declination of about 3/8

– 1/2 inch will be obtained when it is pushed by a finger at the

middle point as shown in Figure 1.

CAUTION: Over tightening the v-belt(s) will result in

overloading of the motor and belt failure, while a loose belt

will be slipping and resulting in an unstable speed,

overheating the belt and high amp draw.

WARNING: Read and understand supplement LV-474 before installing and operating the compressor.

Содержание CA series

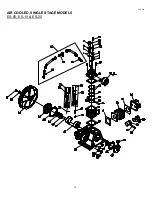

Страница 12: ...CAP 600 12 AIR COOLED SINGLE STAGE MODELS ES 05 ES 10 ES 20 ...

Страница 20: ...CAP 600 AIR COOLED SINGLE STAGE MODEL ES 150A 18 ...

Страница 22: ...CAP 600 AIR COOLED SINGLE STAGE MODEL ES 150B 18A ...

Страница 24: ...CAP 600 20 AIR COOLED TWO STAGE MODELS E 11 E 23 ...

Страница 30: ...CAP 600 AIR COOLED TWO STAGE MODEL E 25 25A ...

Страница 34: ...CAP 600 26 AIR COOLED TWO STAGE MODEL E 35 ...

Страница 36: ...AIR COOLED TWO STAGE MODEL E 57 E57A CAP600 28 ...

Страница 39: ...CAP 600 31 VALVE PLATES DESIGNS FOR E 57 COMPRESSOR ...

Страница 47: ...CAP 600 NOTES 39 ...