Service Manual MCC Cold US 20220700

Page 29

4

Doc. nr.

9124590

Rev.

0

Registration form.

MCC Drop in Unpack instruction

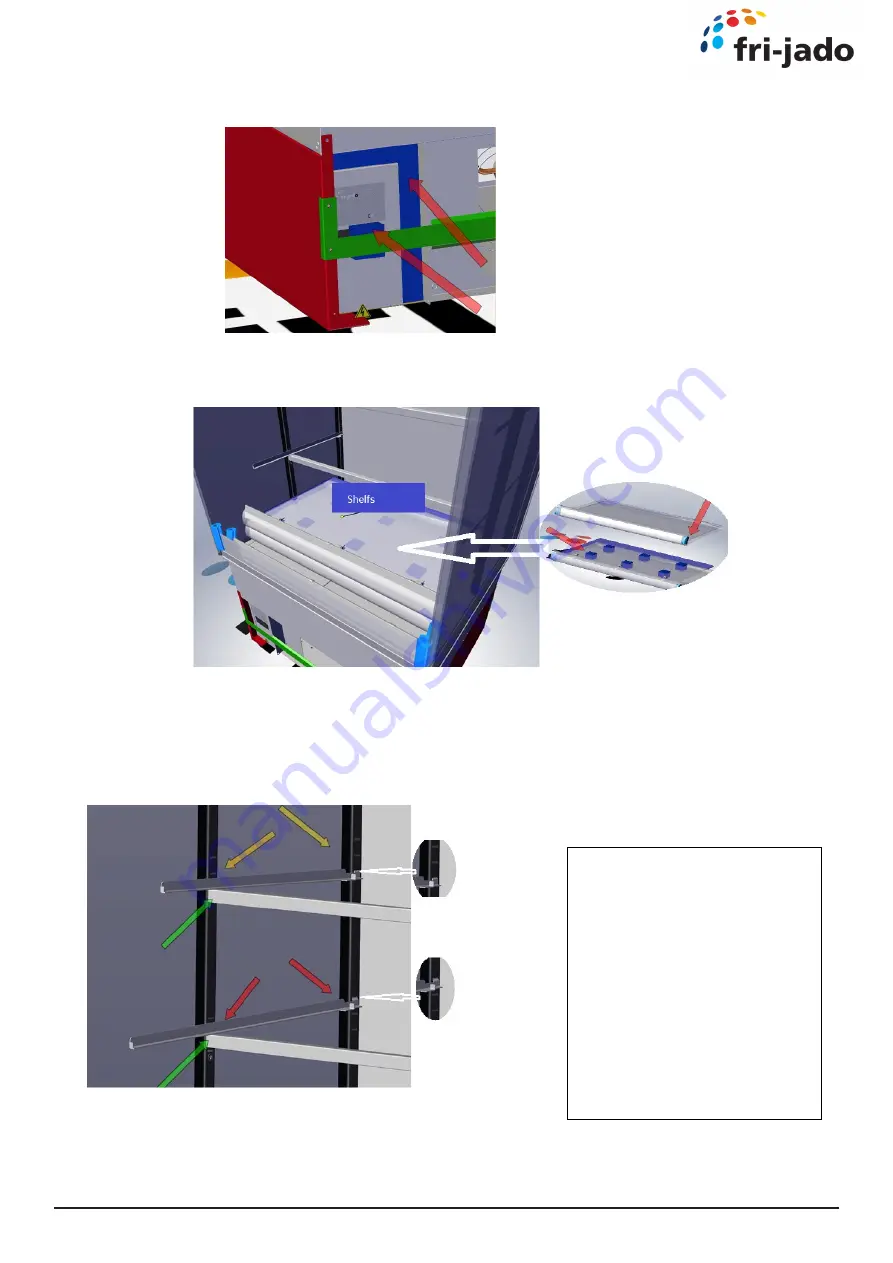

Remove foam which holds the electrical box

Remove documents and glass shelfs from unit.

After placing cabinet in final position, remove tie-wraps which hold the shelf holders.

Make sure the shelf holders are placed in the required sleeve, for the wanted angled or

straight position of the shelfs.

Shelf rails of top shelf should

be placed in lowest position.

Shelf rails of middle shelf

should be placed in highest

position

Содержание MCC 120

Страница 4: ...Page 4 Service Manual MCC Cold US 20220700...

Страница 20: ...Page 20 Service Manual MCC Cold US 20220700 4 1 Connecting drain or evaporation tray...

Страница 21: ...Service Manual MCC Cold US 20220700 Page 21 4 1 Connecting drain or evaporation tray...

Страница 30: ...Page 30 Service Manual MCC Cold US 20220700 5 1 MCC 90 Drop in Dimensions Self Serve...

Страница 39: ...Service Manual MCC Cold US 20220700 Page 39 6 0 Installation Front door section first version...

Страница 79: ...Service Manual MCC Cold US 20220700 Page 79 11 0 Technical Specifications MCC Cold 2 Full Serve US...

Страница 80: ...Page 80 Service Manual MCC Cold US 20220700 11 1 Technical Specifications MCC Cold 2 Self Serve US...

Страница 81: ...Service Manual MCC Cold US 20220700 Page 81 11 2 Technical Specifications MCC Cold 2 Full Serve US...

Страница 82: ...Page 82 Service Manual MCC Cold US 20220700 11 3 Technical Specifications MCC Cold 3 Full Serve US...

Страница 83: ...Service Manual MCC Cold US 20220700 Page 83...

Страница 84: ...Page 84 Service Manual MCC Cold US 20220700 11 4 Technical Specifications MCC Cold 3 Self Serve US...

Страница 85: ...Service Manual MCC Cold US 20220700 Page 85 11 5 Technical Specifications MCC Cold 4 Full Serve US...

Страница 86: ...Page 86 Service Manual MCC Cold US 20220700 11 6 Technical Specifications MCC Cold 4 Self Serve US...

Страница 87: ...Service Manual MCC Cold US 20220700 Page 87...

Страница 89: ...Service Manual MCC Cold US 20220700 Page 89 Page intentionally left blanc...

Страница 102: ...Page 102 Service Manual MCC Cold US 20220700 13 0 Electrical schematics MCC Cold first version...

Страница 104: ...Page 104 Service Manual MCC Cold US 20220700 13 2 Electrical wiring MCC Cold Self Serve N L...