Page 6

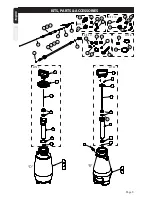

Nozzle Maintenance

1. If nozzle clogs, remove and disassemble the nozzle assembly.

2. Clean the openings of any obstructions and reassemble.

MAINTENANCE CONTINUED

3. Inspect o-ring. If worn or damaged, remove and replace. Lubricate o-ring with petroleum jelly.

(See Figure 4)

4. Inspect check valve in bottom of barrel. If worn or damaged, remove and replace by pressing into

hole in bottom of barrel.

(See Figure 5)

5.

Re-install the barrel into the cap. While holding the cap securely, turn the barrel clockwise to lock the

tabs in place.

Figure 5

“R” Style

1. Inspect gasket. If worn or damaged, remove and replace.

(See Figure 6)

2. To remove pump cap from pump barrel, remove screws securing pump cap to barrel.

(See Figure 7)

3. Inspect o-ring. If worn or damaged, remove and replace. Lubricate o-ring with petroleum jelly.

(See Figure 8)

4. Inspect check valve in bottom of barrel. If worn or damaged, remove and replace by pressing into

hole in bottom of barrel.

(See Figure 9)

5.

Insert the pump handle assembly into the barrel. Align the holes in the pump cap and barrel. Reinstall

screws and tighten securely.

Figure 7

Figure 6

Figure 8

Figure 9

Figure 4