Page 3

Assemble Extension, Shut-Off & Nozzle

1. Install the extension onto the shut-off

assembly and tighten the nut securely.

(See Figure C)

2. Install selected nozzle onto the end of the

extension and tighten securely.

(See Figure D)

Figure C

Figure D

ASSEMBLY INSTRUCTIONS

Assemble Hose To Tank

IMPORTANT: Do not attempt to heat or alter hose,

hose nut, or barb prior to assembly.

1. Align hose barb tabs, push hose barb into tank

until it stops

(See Figure A)

.

2. Slide hose nut into place and turn clockwise to

tighten.

(See Figure B)

.

NOTE: Do not use tools to tighten hose nut.

Figure A

Figure B

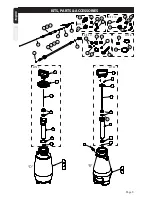

SELECT USING NOZZLE CHART BELOW

(Nozzle selections vary by model)

A. Cap Nut

B. Foaming Nozzle

C. Adjustable Cone Nozzle

D. Red High-Volume Fan Nozzle

E. Yellow Low-Volume Fan Nozzle

F. Flat Seal

G. Adapter

H. Extension

C

A

G

B

D

F

H

E

ADJUSTABLE CONE USES:

Spot spraying in or around flower

beds, trees, and shrubs.

Edging along fences, driveways,

and walkways.

Killing brush such as poison ivy,

poison oak, kudzu and wild

blackberry.

Preparing garden beds for

planting of ornamentals and

vegetables.

For precision spraying in

confined areas such as

gardens and flower beds.

FAN NOZZLE USES:

Lawn replacement. Kill lawn

and weeds before planting a

new lawn.

Preparing large areas for

planting of ornamental and

vegetable gardens.

RED HIGH VOLUME

YELLOW LOW VOLUME

FAN NOZZLE USES:

FOAMING NOZZLE USES:

Spot spraying in flower beds,

walkways, driveways, and

patios, around trees and shrubs.

Edging along fences, driveways

and walkways.

Killing brush such as poison

ivy, poison oak, kudzu and wild

blackberry.