Installation, Operation & Maintenance Guide

Style 79

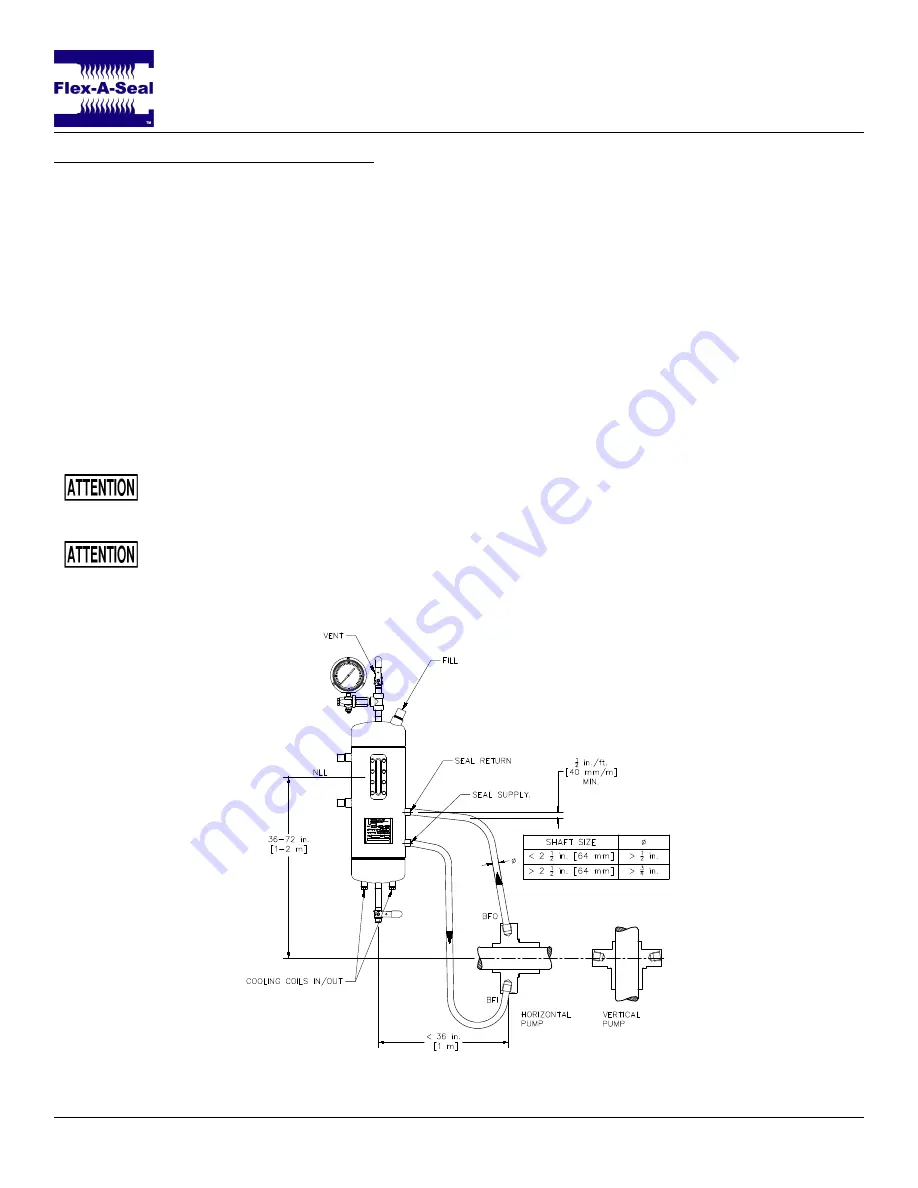

SEAL SUPPORT SYSTEM INSTALLATION

The following steps briefly describe the methods in which a buffer/barrier system should be piped and set up to

support a double cartridge seal. Consult Flex-A-Seal for specific applications and details.

1

. Correctly make connections between the buffer/barrier fluid system and the mechanical seal according to

the connection labels on the prints. In the case of a Piping Plan 52 or Plan 53A the

SEAL SUPPLY

connection (lower port) on the reservoir must lead to the buffer/barrier fluid in (

BFI

) connection on the seal

gland; the

SEAL RETURN

connection (upper port) on the reservoir must lead to the buffer/barrier fluid out

(

BFO

) connection on the seal gland (

Figure 8

).

• Piping should slope continuously upwards (

1

⁄

2

in./ft. [40 mm/m] minimum) with no relative high points

that would result in trapped air in the tubing.

• For shafts smaller than 2

1

⁄

2

in. [64 mm] use at least

1

⁄

2

in. diameter tubing and at least

3

⁄

4

in. tubing for

larger shafts.

• Use smooth, long radius bends in the piping, minimize 90

◦

elbows, and use 45

◦

bends wherever

possible.

Use thread sealant instead of thread tape. Thread tape has been known to break apart and

enter the buffer/barrier fluid stream, resulting in damage to and premature failure of the

mechanical seal.

Ensure that all tubing/piping is free of pipe strain, which can adversely affect the seal.

2

. Flood the seal support system with the recommended buffer/barrier fluid and ensure all air is properly

vented from the seal.

3

. Check for seal leakage.

Figure 8: Typical installation of a buffer/barrier fluid reservoir.

Page 5 of 7