Fax:

+44 (0)115 986 8875

Web:

Tel:

+44 (0)115 9003 600

Filtertechnik

1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731

Certification No. UK002838

20 of 26

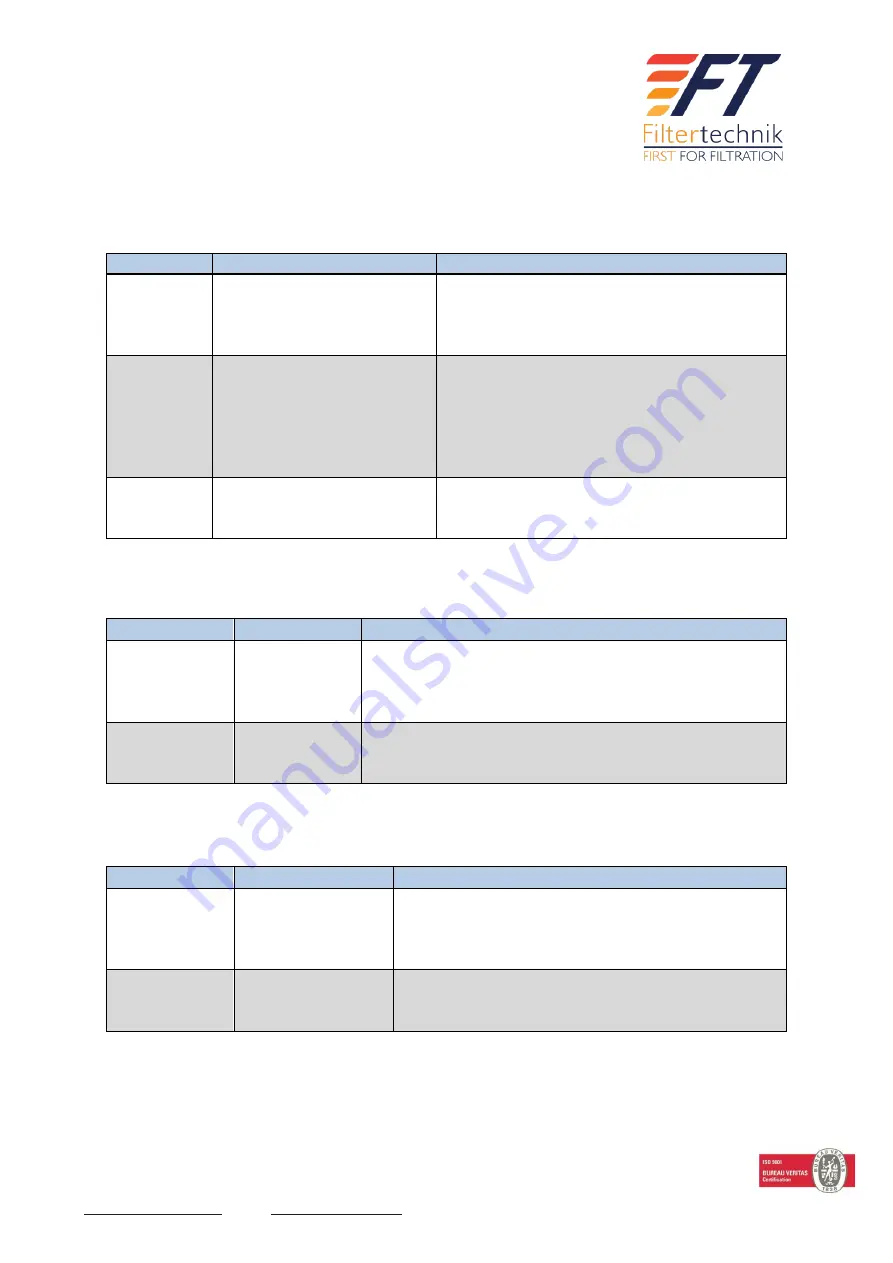

Troubleshooting

General Operational Errors

Problem

Possible Cause

Solution

Unit will not

switch on.

Fully discharged battery.

Connect to the mains and fully charge the unit.

If the LED switches still fail to illuminate there

could be an electrical fault or damage to the

battery pack from over discharge.

Unit will not

prime.

Internal tubing/pump gears

are dry.

High viscosity fluids.

Restriction in the

suction/discharge lines.

Go into the settings for priming to increase the

pump speed.

Raise the height of the fluid sample to gravity

assist, or create a vacuum using a hand operated

thief pump to pull fluid through.

Check the hoses and strainer for blockages.

Screen is

behaving

erratically.

Dirt on the screen or hands.

Wipe the screen clean to remove traces of dirt or

oil. In most cases gloves will not work with the

touch screen.

Particle Counting

Problem

Possible Cause

Solution

Contamination

codes dropped

to near zero

A blockage in

the flow path

Check there is adequate flow going through the unit

(approximately 20-100ml/min)

Check/clean the suction strainer for any contamination

Erratic count

levels

Unstable

sample

Check for the presence of air. Bubble counts should be

maintained below 200 bubbles/ml in each channel.

RH & Water Content

Problem

Possible Cause

Solution

Water content

is above 95%

High moisture levels

in the sample.

Damaged moisture

sensor.

Flush the unit immediately with dry oil to avoid damage

to the moisture sensor. If levels still don’t fall the sensor

could be permanently damaged.

Water content

bouncing from

near 0 to 100%

Damaged moisture

sensor.

Permanent damaged due to excessive moisture. Sensor

will require replacing.