Ä

7.4

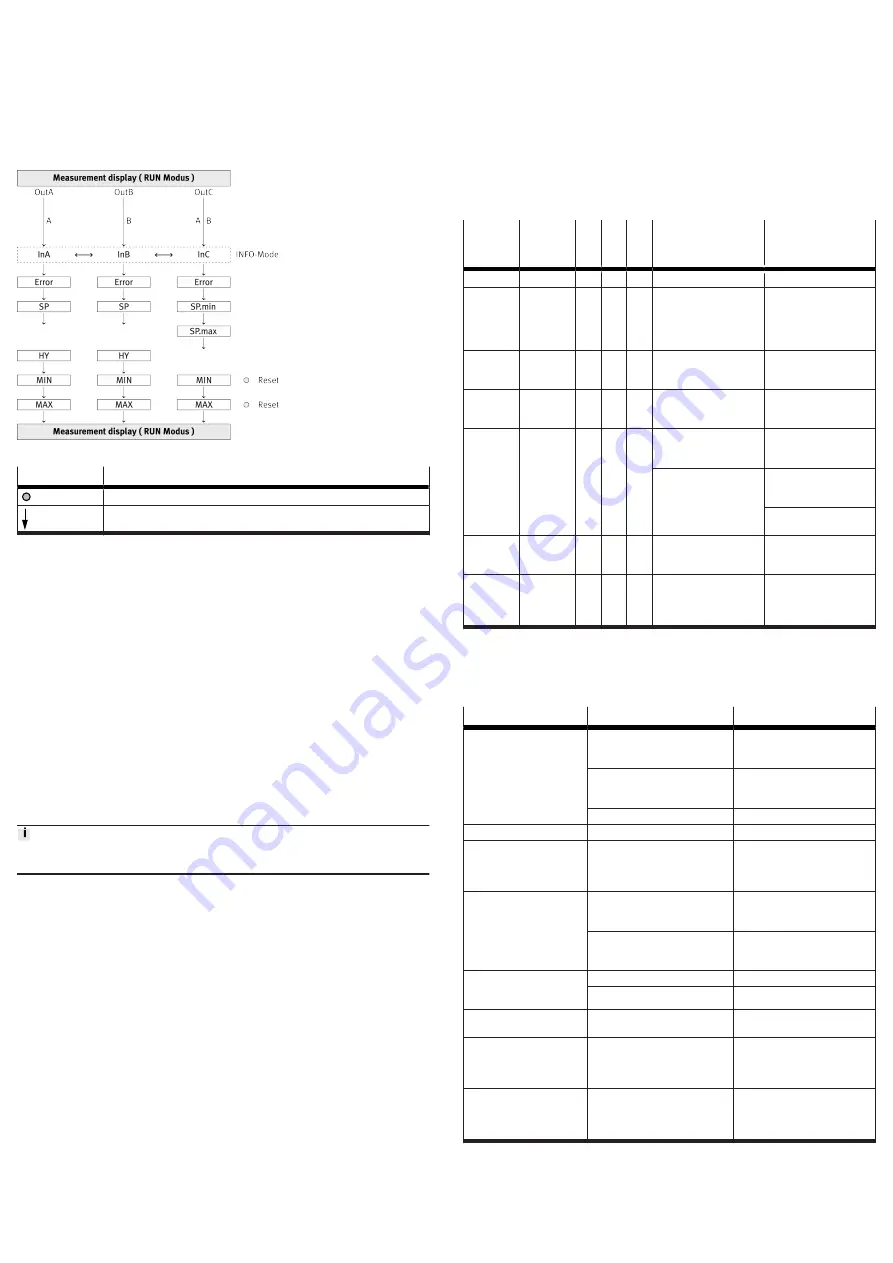

Displaying parameters (INFO/SHOW mode)

Requirement: the sensor is ready for operation (RUN mode).

1. Press A button, B button or A and B button.

Ä

Display shows the relevant input value or an error number.

2. To display each of the following parameters, press the A button, B button or A

and B button .

3. At the end of the SHOW mode, the relevant minimum and maximum values

are displayed. To reset the display of the minimum and maximum values,

press the Edit button.

Ä

RUN mode is active.

Fig. 14: Measured value indicator for SHOW mode

Key

Meaning

Edit button

A button, B button or A and B button

Tab. 17: Legend for measured value indicator (RUN mode)

8

Operation and use

8.1

Notes on operation

Type SOPA-C..

•

To prevent contamination of the sensor modules and the measuring nozzles,

switch on the measuring air.

•

Activate the exhaust air to clean contaminated measuring nozzles.

The switching status of the valves, which are integrated in the control module and

used for activating the measuring and exhaust air, is indicated by the status LED

[Sense] and [Clean].

Type SOPA-C..-H

•

The electric manual override function for the measuring and exhaust air on

the control module can be deactivated by switching off the supply voltage for

the manual override.

Ä

The LED which indicates the ready status of the manual override is then

switched off.

8.2

Restoring Factory Settings (Restore)

By resetting to the factory settings, the current settings are lost. Note down

current settings before resetting.

1. Switch off operating voltage.

2. Press and hold the A pushbutton, B pushbutton and Edit button.

3. Switch on the operating voltage.

–

[CLER] is displayed.

–

The factory settings are restored . RUN mode is active.

8.3

Using the differential pressure regulator

In order to enable faster response times with low measuring distances or com-

pletely sealed measuring nozzles, a differential pressure regulator (LRLL-1/8-

QS-6) can be used instead of the vent screw. The valve function enables the

pressure to be exhausted significantly quicker than via the vent screw.

Connecting and checking the differential pressure regulator

1. Remove the vent screw (SW 14).

2. Mount the differential pressure regulator (LRLL-1/8-QS-6) n the connection

for the vent screw (

3. Press the CLEAN pushbutton (CLEAN = OFF) and then the SENSE pushbutton

(SENSE = ON) on the control module.

4. Make sure that there is not an object in the area of the measuring nozzles .

5. Turn the adjusting screw on the differential pressure regulator clockwise

(towards LOW) until air stops flowing from the differential pressure regulator.

6. Turn the adjusting screw on the differential pressure regulator anticlockwise

(towards HIGH) until air starts to flow from the differential pressure regulator.

Checking the settings of the differential pressure regulator

1. Seal the measuring nozzle (e.g. workpiece inserted).

2. Press the CLEAN key (CLEAN = OFF) on the control module.

Ä

Sensor module is supplied with operating pressure. [SUP.P] is displayed.

3. Press and hold the SENSE pushbutton (SENSE = ON) on the control module

until [SUP.P] is no longer displayed.

4. If the delay ([SUP.P] in the display) is too great, reduce the time by turning the

control valve (towards HIGH).

9

Maintenance and Care

1. Switch off the energy sources (operating voltage, compressed air).

2. Clean sensor with non-abrasive cleaning agents.

10

Malfunctions

10.1

Error messages

Indica-

tion on

display

Event

code

[hex]

G

1)

E

2)

S

3)

Error

Remedy

[Er01]

0x5000

4

3

4

Sensor module defective

Replace sensor module

[Er14]

0x180E

2

2

1

Supply pressure (InC)

outside the measuring

range (

>

2 bar,

>

0.2 MPa); signal cannot

be evaluated

Observe the measuring

range

[Er17]

0x5111

4

3

3

Undervoltage in supply

voltage

Observe the voltage

range

[Er21]

0x1815

4

3

4

Short circuit/overload at

switching output OutA

(only for SOPA-...-PNLK)

Rectify short circuit/over-

load.

[SUP.P]

0x1815

2

2

1

Supply pressure

switched off

Apply supply pressure

Exhaust air in the system

Wait until the exhaust

air has completely dissi-

pated from the system.

Use/set differential pres-

sure regulator.

[Er.Co]

IO-Link communication

errors

Check line OutA.

Check settings of the

device sensor.

[Er.Id]

IO-Link device ID error,

devices are not identical

When replicating, use

sensors with the same

pressure range/type

(same device ID).

1) device status

2) IO-Link event type

3) diagnostic level

Tab. 18: Error messages, error codes, diagnostic levels and error description

10.2

Fault clearance

Fault description

Cause

Remedy

No indication on display

Supply voltage not applied or

permitted operating voltage not

present

Switch on the supply voltage;

maintain the voltage range.

Electrical connections swapped

(incorrect polarity)

Connect the sensor module in

accordance with the plug pat-

tern.

Sensor module defective

Replace sensor module.

Incomplete display

Display faulty

Replace sensor module.

Incorrect pressure indicator

for supply pressure (InC)

Sensor module contaminated

Replace the sensor module and

operate the sensor only with fil-

tered compressed air

Measured value indicator

(7-segment) flashes

Value InC (supply pressure)

outside the measuring range

(

>

2 bar)

Maintain pressure range

Overpressure above permitted

overload pressure (device dam-

aged)

Replace sensor module.

Outputs do not switch in

accordance with the set-

tings

Short circuit or overload at output Correct short circuit or overload.

Sensor module defective

Replace sensor module.

Settings cannot be edited

(Lock)

Access protection active

Enter security code or reset

device to factory setting.

Long response times after

the CLEAN function with vir-

tually closed or completely

closed measuring nozzles

Pressure reduction for the meas-

uring nozzle too slow

Replace the vent screw with a

differential pressure regulator

"Sensor ready for opera-

tion" display not showing

when using a differential

pressure regulator.

No pressure reduction for the

measuring nozzle

Adjust the differential pressure

regulator

Tab. 19

11

Disassembly

1. Switch off the energy sources (operating voltage, compressed air).

2. Disconnect the connections for the control module and the sensor modules.

3. Remove device.