4. Clean the shaft of the motor

1

.

The coupling will only grip without slipping on a shaft pin which is dry and free of

grease.

If fat solvent media enters the bearing, it will wash out the service life lubrica-

tion of the bearing.

Note

Encoder and brake can be destroyed.

• Do not exceed the maximum axial shaft load (

Technical Data).

5. Place the EMMS-ST on the motor flange

2

.

6. Connect the motor to the mechanical components at the threaded holes

3

.

Ready to use motor kits for drives can be found in the Festo accessories

(

Accessories).

7. Tighten the fastening screws (

Instructions on drive and motor kits).

5

Commissioning

Note

The actuators connected to the motor can be started unexpectedly when the

holding brake is energised.

• Make sure that the motor is held to a controlled position by the controller

when the holding brake is energised/released.

• Complete the commissioning of the motor in conjunction with the controller in

accordance with the controller manual.

6

Operation

Warning

Hot parts of the housing can cause burning.

• Make sure that people and objects cannot come into direct contact with the

motor.

7

Maintenance and care

Warning

Layers of dust can catch fire.

• Clean the motor housing of dust regularly.

8

Disassembly and repair

Warning

Masses which suddenly slide down may cause injury to people.

• Make sure that the work load on the drive is in a safe position (e.g. in the case

of a vertical drive: in the lower end position).

• You can now remove the EMMS-ST from the mechanical components.

If repairs are required:

• return the motor to Festo.

Repairs by Festo will maintain the safety standards.

• Complete the fitting as follows:

1. Push the slide or the cantilever of the driven mechanical components into a safe

position.

2. Fit the motor kits in accordance with the specifications in the assembly instruc-

tions.

9

Accessories

Note

• Please select the accessories you need from our catalogue

(

www.festo.com/catalogue).

10

Troubleshooting

Malfunction

Possible cause

Remedy

Motor shaft does not turn

Load too high

Reduce motor load

Motor shaft does not turn

Controller has not yet been

enabled

Check controller signals

Holding brake active (only

with EMMS-ST-…-SB/-SEB)

Release holding brake

Motor shaft rotates in the

wrong direction

Cabling fault

Check cabling

Motor stops at wrong position

Stepper fault

Repeat reference run

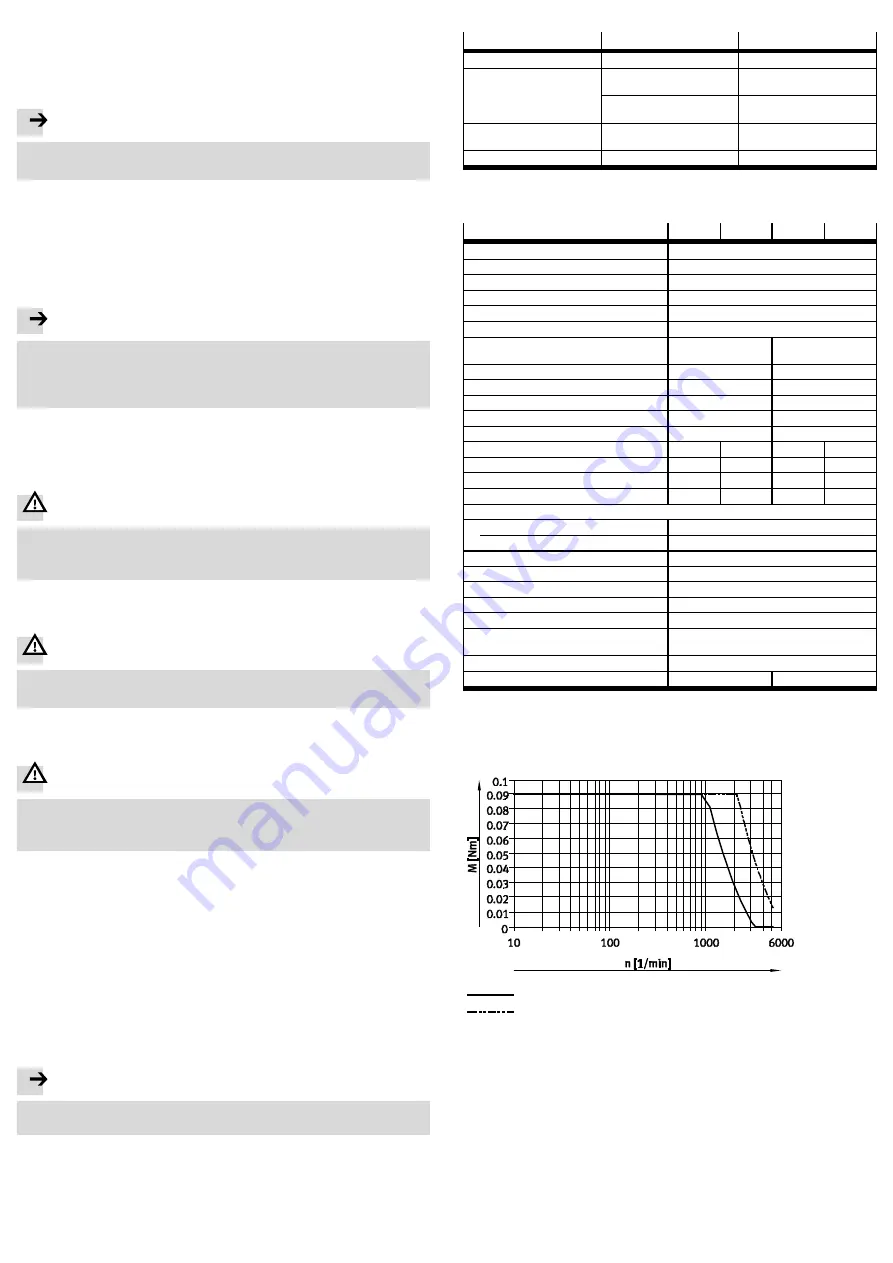

Fig. 4

11

Technical data

EMMS-ST-28-L-…

S

SE

SB

SEB

Nominal motor operating voltage

[V]

48

Nominal motor current

[A]

1.4

Motor holding torque

[Nm]

0.09

Step angle with full step

[°]

1.8 ± 5 %

Winding resistance

[Ω]

2.3 ± 15 %

Winding inductance at 1 kHz

[mH]

1.4 ± 20 %

Total moment of inertia of drive

output

[kgcm

2

]

0.018

0.025

Brake operating voltage

[V]

–

24

Brake power consumption

[W]

–

8

Brake holding torque

[Nm]

–

0.2

Brake response delay

[ms]

–

6

Brake separation time

[ms]

–

10

Pulses / revolution

–

500

–

500

Zero pulse

–

Yes

–

Yes

Line driver (RS422 protocol)

–

Yes

–

Yes

Operating voltage of encoder

[V]

–

5

–

5

Radial shaft load:

5 mm distance from flange

[N]

58

20 mm distance from flange

[N]

20

Axial shaft load

[N]

7

Insulation protection class

B (130 °C)

IP protection (when installed)

IP65

Ambient temperature

[°C]

–10 … +50

CE mark (see declaration of conformity)

1)

To EU EMC Directive

Relative air humidity

(non-condensing)

[%]

45 … 80

Max. cable length

[m]

15 (see documentation for controller)

Product weight

[kg]

0.32

0.38

1)

Measures may need to be implemented in residential areas for interference suppression

Fig. 5

12

Characteristic curves

Rated voltage 48 V

24 V DC

48 V DC

Fig. 6