8.

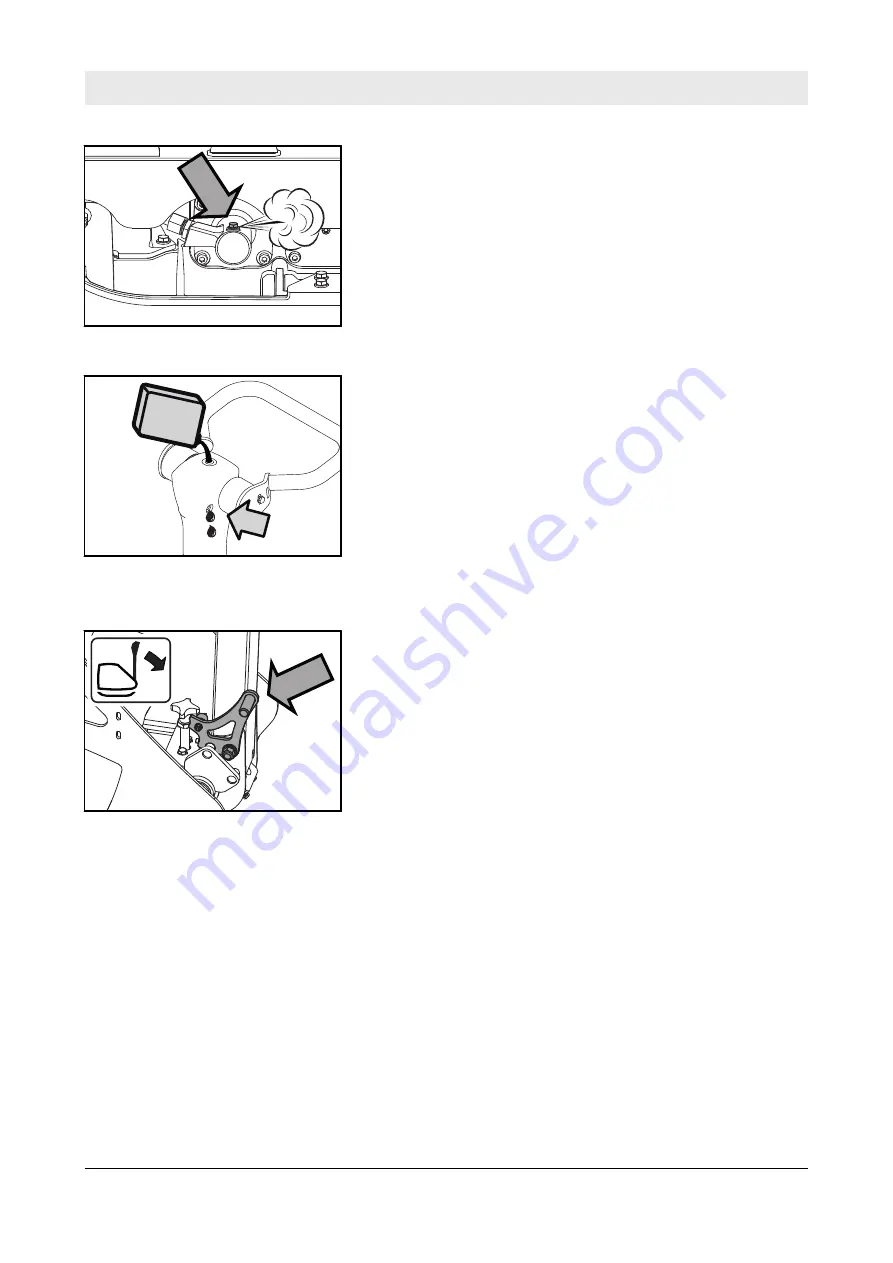

Place a cloth underneath the bleeding screw to collect

leaking oil.

9.

Slacken the bleeding screw.

10.

Wait until all air has escaped and then tighten the bleeding

screw.

11.

Place a cloth underneath the filler bore to collect leaking oil.

12.

Fill with oil through the filler bore until it starts to run out

through the level inspection bore.

13.

Retighten the filler and level inspection plugs.

14.

Pull the locking pawl lever and fold the steering rod down.

B-695-0164

Fig. 121

HV 32

B-695-0017

Fig. 122

Concluding work

B-695-0154

Fig. 123

Maintenance – Annually

DRP15X

97

Содержание DYNAPAC DRP15X

Страница 6: ...Table of contents DRP15X 6 ...

Страница 7: ...1 Introduction Introduction DRP15X 7 ...

Страница 11: ...2 Technical data Technical data DRP15X 11 ...

Страница 15: ...3 Concerning your safety Concerning your safety DRP15X 15 ...

Страница 39: ...4 Indicators and control elements Indicators and control elements DRP15X 39 ...

Страница 45: ...5 Checks prior to start up Checks prior to start up DRP15X 45 ...

Страница 53: ...6 Operation Operation DRP15X 53 ...

Страница 62: ...Operation Parking the machine in secured condition DRP15X 62 ...

Страница 63: ...7 Loading transporting the machine Loading transporting the machine DRP15X 63 ...

Страница 68: ...Loading transporting the machine Transport wheels DRP15X 68 ...

Страница 69: ...8 Maintenance Maintenance DRP15X 69 ...

Страница 109: ...9 Troubleshooting Troubleshooting DRP15X 109 ...

Страница 116: ...Troubleshooting What to do if the engine has flooded DRP15X 116 ...

Страница 117: ...10 Disposal Disposal DRP15X 117 ...

Страница 119: ......

Страница 120: ......