46

Table 9

Application

Bulb indication

Nos. per tractor

Headlights (main and dipped beam)

H4 12V 60/55 W

2

Front and rear work lamps

H3 12V 55W

8

Front marker lights

12V 5W

2

Rear marker lights and stop lights

12V 5/21W

2

Flashing indicators (front and rear)

12V 21W

4

Number plate illumination

12V 5W

1

Cab lighting

12V C5W

1

Illumination of instrument panel gauges and

indicator lights

12V 1,2 WBC

14

5.5. Hydrostatic steering system.

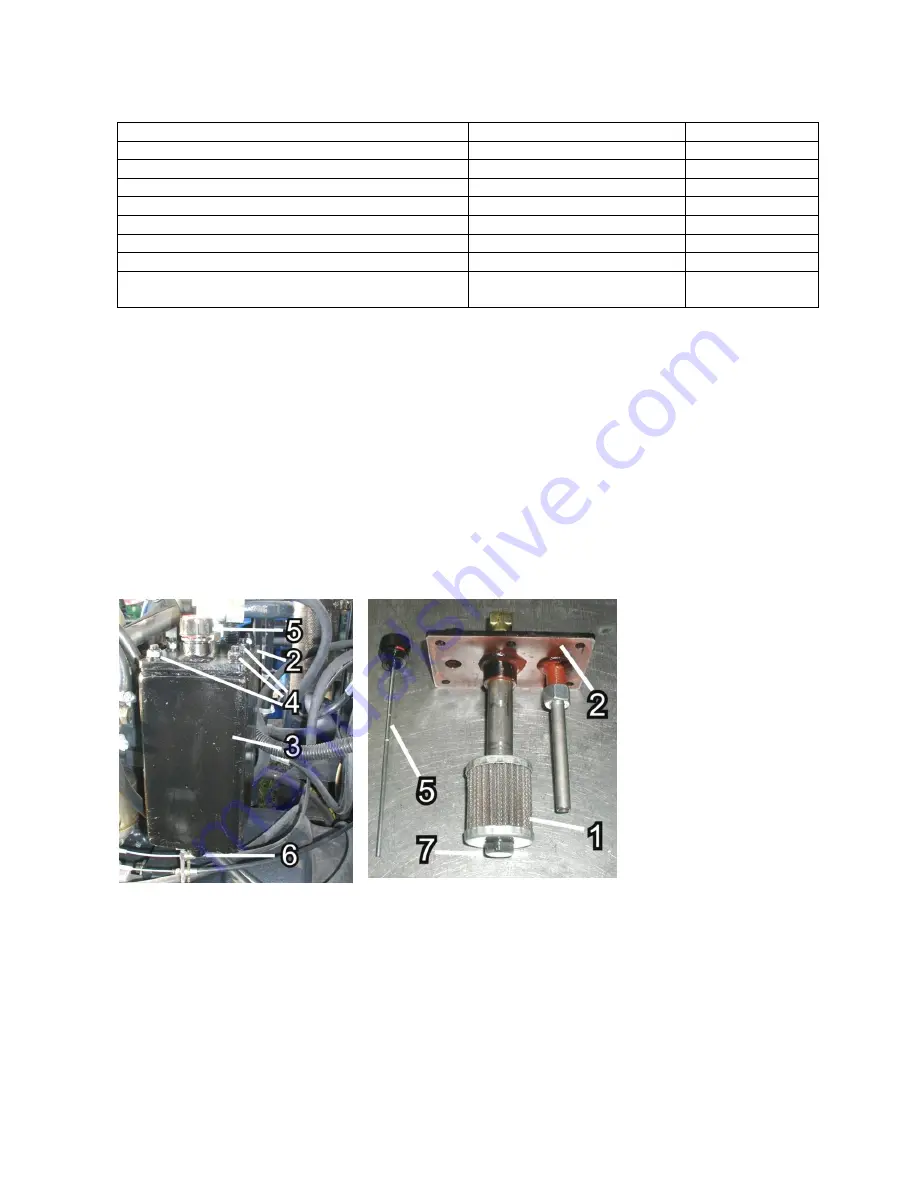

Hydrostatic steering system has an independent circuit with its own oil reservoir

(Fig. 5.5.1).

There is an oil filter in the reservoir. Replace the filter element every 600 hours of operation.

To replace the filter, drain the oil from the reservoir, remove the reservoir cover (2), remove the filter

element and install a new one.

Drain the oil by plug (6) located at the bottom of the reservoir - after unscrewing drain plug unscrew

also the filler plug with vent (5). The reservoir cover is removed by unscrewing screws (4) located on

the top of the reservoir. The filter is removed by unscrewing the screw (7).

After replacing the filter, follow the assembly steps and fill the system with fresh oil

Free play in the system is measured on the circumference of the steering wheel when the front

wheels are set to ride forward and should not exceed 5

O

with the engine running.

Fig. 5.5.1. Hydrostatic steering

oil reservoir:

1 - Filter element. 2 - Oil

reservoir cover. 3 - Oil

reservoir housing. 4 - Cover

securing bolt. 5 - Filler plug

with oil level dipstick.

6 - Drain plug. 7 - Filter

securing nut.

5.6. Front axle.

5.6.1. Non-driven front axle

Grease points

Every 150 hours of operation grease front axle pivot pins (Fig. 5.6.1), stub axles and front wheel hubs

(Fig. 5.6.2) grease points.

Содержание 675

Страница 1: ...Kullanım Kılavuzu Farmtrac 675 675DT ...

Страница 62: ...62 8 WIRING DIAGRAMS FT 675 WIRING DIAGRAM without cab ...