FARMI 260

27

2

72 + 0,5

_

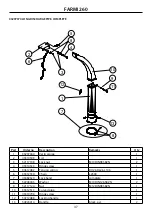

The remaining knives are adjusted as follows:

1. Measure the knife-to-chamber distances for both

ends of the adjusted knife. The knife-to-chamber

distance is the distance between the edge of the

knife and the frame chamber, see Fig. 29.

2. The remaining knives are adjusted so that the knife-

to-chamber distances of all knives are equal.

3. Tighten the knife bracket fastening bolts to 250 Nm.

4. Check all knives by measuring.

5. Check the knife-to-anvil clearances according to

Section ”Adjusting and checking the knife-to-

anvil clearance”.

Fig 29. Knife-to-chamber distance

REPLACING THE SPLINED SHAFT

1. Remove the upper chamber.

2. Remove the bearings (Fig 32). Welding damages the

bearings.

3. Lift the cutting disk using a crane.

4. At a distance of 2 mm from the shaft end, grind a

groove of 15 mm depth into the shaft See fig 30.

5. Heat the joint area, if necessary.

6. Move the splined shaft so that it comes loose and

can be removed.

7. Clean the shaft hole and install the new shaft.

8. Make a fillet weld up to the surface level with three

runs. Use ESAB 68.81, OK 48, OK Femax 38.65, or

equivalent filler.

Grind a 15-mm-deep groove

about 2 mm from the end of

the shaft.

Fig 30. Replacing the splined shaft

Area to be heated