FARMI 260

24

A

B

30

o

45

o

R~

20

0

7

7

/

8

”

(0,01”)

0,3 mm

45

o

30

o

(0,01”)

0,3 mm

SHARPENING THE KNIVES

Sharpen all knives equally. This

ensures disk balance.

Avoid heating the knife during

sharpening.

The knives need sharpening when:

•

The self-feeding of wood has decreased

•

The power demand has increased

•

The chip surface is rough

•

The individual chips have become smaller.

Normally, the knives can be sharpened several times

without actually being removed (with, e.g., a sharpening

stone or belt grinder).

More thorough conditioning is carried out with a

surface grinder, with the knives removed.

The new knives are sharpened to a concave shape,

R=200. The sharpening angle is 30° and hone angle is

45° . The hone angle prevents the edge from breaking.

Fig. 18.

It is recommended that the knives be sharpened to a

concave shape. If this is not possible, the knife is shar-

pened to a flat profile. Fig. 19.

Fig 18. The profile of a concave knife

Fig 19. A knife with a flat profile

shar

pening st

one

knife

knife

The hone angle is ground to a 45° angle with two to

three longitudinal strokes, using a level sharpening

stone.

Burrs are removed from the knife fastening bolt side,

grinding with the surface. Fig 20.

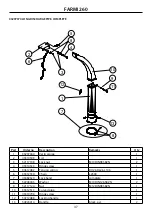

REMOVING THE ANVILS

The chipper features both a vertical and horizontal anvil.

To remove the anvils, open the fastening bolts (A) and

(B) (M16). The horizontal anvil fastening bolt (B) is

located below the feed opening. Fig. 21.

SHARPENING THE ANVILS

If you notice wear or rounding of the inner edge of

the vertical anvil, sharpen the anvil so that the original

angle is retained. Fig. 22.

Fastening bolt side

Fig 20. Final grinding of the knife

Fig 21. Anvil fastening bolts

CAUTION!

!

Vertical anvil

Horizontal anvil

Knife