MAINTENANCE, LUBRICATION AND

ADJUSTMENT INSTRUCTIONS

JL 601

B // En // 141001MRu

www.normet.fi

Normet Corporation

Ahmolantie 6

FIN --- 74510 PELTOSALMI

FINLAND

Tel. + 358 (0) 17 83 241

Fax. + 358 (0) 17 823 606

18

Page

8. SAFETY

Disengage the P.T.O and turn

the tractor off before you

service the winch, remove the

keys so the tractor cannot be

started up accidentally.

DANGER!

9. LUBRICATION

Do not oil the drive chain,

because the oil will work its

way to the clutch!

NOTE!

The cable drum, main sprocket and

snatchblock are fitted with self lubricating

bearings.

Following points require lubrication:

1. Grease the drum clutch parts after every

500 working hours. Always use good

quality lubrication grease.

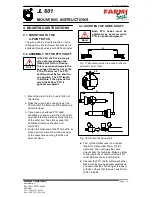

2. Grease the PTO---shaft regularly and

aways before use as shown in figure 31.

3. Grease the drum chain lightly (not with oil)

after every 50 working hours with spray type

, hardening chain grease. Wipe off the

excessive grease.

Swing joints sideways for greasing

8h

8h

h= working hours

20h

Apply grease

inside the

outer telescopic profile

When used in winter the

guard tubes must be grea-

sed to avoid freezing.

Fig. 31. P.T.O shaft lubrication.

10. SERVICE

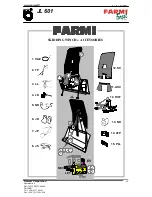

10.1. CLUTCH ADJUSTMENT

1. Loosen the nuts A and B at both ends of

the drum axle. Wrench opening 1

7

/

16

” (36

mm).

2. Adjust the clutch by turning the axle C with

9

/

16

” or 14 mm wrench. The clutch

tightens clockwise, loosens

counterclockwise. Turn max. 1/4 turn.

3. After adjustment retighten the nuts A and

B on the ends of the drum axle.

4. Pull the control rope. The lever should

move up 1.5” (4cm) before the clutch

engages. If the clutch engages earlier

loosen the clutch setting.

A

B C

Fig. 32. Clutch adjustment.