GB

TOOL IDENTIFICATION

The riveting tool

KJ 60

is identified from a marking that

shows company name and address of manufacturer,

designation of the tool, CE mark and year of

manufacturing. If any service is requested, please make

reference to the data shown on the marking.

KJ 60

Company name and

Designation of the tool

address

KJ 60

Year of manufacturing

GENERAL NOTES AND USE

The tool can be employed only for threaded inserts with thread

of

M3 ÷ M8

diameter.

The

KJ 60

oil pneumatic system assures more power than the

pneumatic system used for other models. That means a

reduction in the problems due to the wear and tear of the

components, therefore, there will be an increase in reliability.

The technicai solutions adopted reduce the dimensions and

the weight of the tool which, for these reasons, make it very

handy. The possibilities of leakage from the oil-dynamic

system, are eliminated by some sealed gaskets, which solve

this problem.

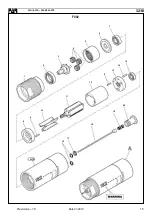

MAIN COMPONENTS

A) ..................

Threaded tie rod

B) ..................

Head

C) ..................

Ring nut clamping head

D) ..................

Tensile strength pushbutton

E) ..................

Unscrewing pushbutton

F) ..................

Insertion Pin Hole Dechucking clutch

G) ..................

Regulation stroke ring nut

H) ..................

Balancer connection

I) ....................

Pneumatic motor

L) ...................

Oil tank plug

M) ..................

Compressed air connection

N) ..................

Protection bottom

295

80

F

G

H I

Ø 24

Ø 35

A

L

B

288

C

D

E

KJ 60

M

N

Ø109

TECHNICAL DATA

• Working pressure.....................

6 BAR

• Min. int. diam. of the compressed air

feeding hose

min. diam = 8 mm

• Air consumption per cycle........

9 Nl

• Max power.......

6 BAR -13656 N

• Weight.............

2,212 Kg

• Working temperature........

-5°/+50°C

• Root mean square in total acceleration frequency (Ac)

to which the arms are subjected

< 2.5 m/s2

• A-weighted emission sound pressure level .............

70 dBA

• Peak C-weighted instantaneous sound pressure

<130 dBC

• A-weighted emission sound pressure .....................

88 dBA

AIR FEED

The air feed must be free from foreign bodies and humidity in

order to protect the tool from premature wear and tear

of the components in movement, therefore we suggest to

use a lubrificator group for compressed air.

8

Date 01-2012

Revisione - 18

Содержание KJ 60

Страница 3: ...RU 3 GB INSTRUCTIONS FOR USE 7 RU 12 GB SPARE PARTS 13 PL...

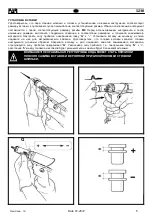

Страница 6: ...M8 G G G h G Revisione 18 Date 01 2012 5...

Страница 7: ...1 25 2 3 4 1 2 25 mm 3 4 25 6 Date 01 2012 Revisione 18...

Страница 16: ...SPARE PARTS F002 7 6 5 4 3 15 2 14 13 9 1 12 11 20 10 19 9 8 18 17 16 KIT A Revisione 18 Date 01 2012 15...

Страница 17: ......

Страница 18: ......