19

GB

KJ 45/S

KJ 45/S

Revisione

-

08

Date

07-2016

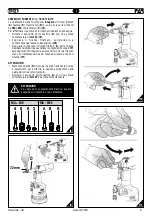

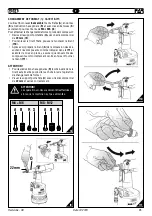

TOPPING UP THE OIL-DYNAMIC CIRCUIT

(fig.

f17-f18

)

The oil-dynamic circuit should be topped up after a long period

of work or when there is a power loss of the riveting tool.

Put the riveting tool (not fed) in a vertical position rotating

the knob (

M

) towards the sign “

+

” up to the end of stroke,

and remove the plug (

I

) by means of a

4 mm

Allen wrench

(equipped). During this operation check the oil level in order

to avoid any overflowing. Then pour the oil

HLP 32 cSt

into

the oil container (

T

) (equipped) which shall be screwed to

its seat on the plug (

I

).

While keeping the riveting tool in vertical position and starting

air feeding, push the button (

D

) and make the riveting tool

carry out some cycles until air bubbles inside the container

stop coming out. This condition indicates that the topping

up of the oil has been fully achieved. At this point stop the

air feeding and while keeping the riveting tool in a vertical

position, unscrew and close the oil container (

T

) and the

plug (

I

) checking the soundness of the hermetic washer and

repeat all the adjustments for placing the insert as indicated

at page 14-15.

ATTENTION:

It is very important to follow the above-

mentioned instructions and use gloves during oil topping up.

If you need to empty completely the hydraulic circuit, you

must put the oil in a suitable container and contact a company

authorized to dispose of wastes.

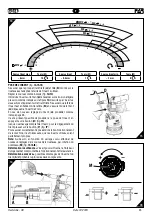

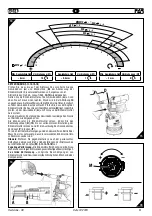

MAINTENANCE

Daily maintenance

- Check that the threaded tie rod is not damaged.

- Check the supply system of the compressed air.

- Check that the stroke of the tool is suitable for the selected

insert to clamp (see the pertaining instructions for adjusting

the stroke, indicated at page 14).

- Check that there are neither air nor oil leakages. In this

case replace possible damaged connectors or seals.

- Check that the supply pressure of the compressed air does

not exceed

7 bar.

Weekly maintenance

- Check the oil level controlling the stroke of the riveting tool.

If necessary fill up for preventing failures of the riveting

tool as indicated (fig.

f18

).

Overhaul of the riveting tool

It is advisable to carry out a complete overhaul of the riveting

tool after

600,000 cycles

or

every year.

In this case apply only to centres authorized by

FAR S.r.l.

DISPOSAL OF THE RIVETING TOOL

Follow the prescriptions of the national laws for

disposing of the riveting tool.

After disconnecting the tool from the pneumatic

system, disassemble and split all the components

according to the material: steel, aluminium, plastic

material, etc.

Then proceed to scrap the materials in accordance

with current laws.

ATTENTION!

Before disconnecting the compressed air hose,

make sure that it is not under pressure!

ATTENTION:

Make sure that the oil filler cap (

I

)

is tightened at a torque corresponding to

Min. 5

Nm ÷ Max. 8 Nm.

We recommend to use oil

HLP 32 cSt

or similars.

f17

f18