GB

KJ 45/S

KJ 45/S

14

Date

07-2016

Revisione

-

08

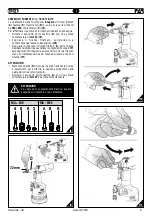

AIR FEED

(fig.

f1

)

The compressed air system must be provided with air

cleaners and condensation drains and must guarantee that

the air supplied to the feeder has a constant pressure of min

6 bars

. The regulator must be set at a pressure of

6,5 bars

.

Connect the machine to the main compressed air supply as

shown in the diagram (

f1

):

1

) Cutoff cock (used during maintenance of the filter regulator

or of the lubricating unit).

2

) Main supply inlet.

3

) Main supply bleed.

4

) Pressure regulator and filter (bleed daily).

5

) Lubricating unit.

ATTENTION!

The riveting tool is equipped with a

relief valve (

F

) starting when the compressed-air

pressure significantly exceeds 7 bar.

ATTENTION!

If the relief valve (

F

) starts and the air

consequently escapes, we recommend to check if

the tool feed pressure corresponds to the pressure

value indicated under the technical data in this

handbook (page 13).

FRL UNIT

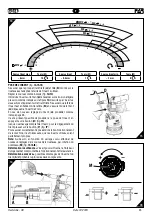

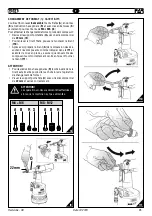

PRELIMINARY OPERATIONS

(fig.

f2-f3

)

Check that the threaded tie rod (

A

) and head (

B

) couple

assembled on the riveting tool is suitable to the size of the

insert to clamp; otherwise change the size (page

17). The

tie-rod (

A

)/head (

B

) unit assembled on this riveting tool,

corresponds to a

M10

thread.

Before using the riveting tool and after each change of size, the

stroke should be adjusted according to the dimensions, type

of the insert and thickness of the material to clamp. Before

carrying out this operation rotate the knob (

M

) according

to the direction of the arrow, (

+

) for increasing the stroke

and (

-

) for decreasing it. Increasing the stroke - rotation of

knob (

M

) - in the direction indicated with the symbol (

+

), the

distance “

h

” (page 15) decreases increasing the clamping

action. To verify that the stroke is correctly adjusted check the

indicator (N) comparing it with the values of the table (fig.

f3

).

NOTE:

Before the definitive placing of the insert, its clamping

on the thicknesses involved should be checked, carrying

out other adjustments, as shown at page 18 (the specified

adjustments are just an indication, it is advisable to see the

technical data of the inserts used).

ATTENTION!

The incorrect adjustment of the

riveting tool can cause a bad clamping of the

inserts and a possible break of the tie rod!

ATTENTION!

The above-mentioned operations

must be done when the tool is not fed. For

visualizing the changed stroke (

N

) the tool

must be fed.

f2

1

2

4

5

3

3 m Max

f1

F

Q

• Move up the slider of the air-entry valve (

Q

) to feed the tool.

• Before regulating the stroke, discharge the tool by the air and stop

the feeding, moving down the slider of the air-entry valve (

Q

).