4

Inlet

Burner pressure

pressure

at manifold

Natural Gas 20mbar 14mbar (+/- 0.75mbar)

Propane Gas 37mbar 34mbar (+/- 1mbar)

The incoming service must be of sufficient size to supply

full rate without excessive pressure drop. A gas meter is

connected to service pipe by gas supplier. Any existing

meter should be checked preferably by gas supplier to

ensure that it is adequate to deal with rate of gas

supply required.

Installation pipe work should be fitted in accordance with

IGE/UP/2. The size of pipes from meter to unit must not

be less than that of appliance inlet connection. A 3/4" BSP

inlet connection is fitted to unit.

An isolating valve must be located close to the appliance

to facilitate shut down during an emergency or routine

servicing. The cock must be easily accessible to the user.

The installation must be tested for gas soundness as

stated in IGE/UP/1.

Domestic type, flexible rubber tube connections

must NOT be used with this appliance.

Only tube complying with BS669 Part 2, Specification

for corrugated metallic flexible hoses for catering

appliances, shall be used.

1.5 ELECTRICAL SUPPLY

The unit is equipped with a 3-core flexible cord with

standard 3 pin plug fitted with a 13A fuse. A regular

13A socket outlet can be used.

If supply is through a distribution fuse box, this must be

via a fuse with a maximum rating of 13A.

In the event of mains cable being replaced, any new

cable should comply with 60245 IEC 57 designation.

(H05 RN - F)

Rated Voltage

Rated Current

G401F/G402F 230V~

3.55amps

THE APPLIANCE MUST BE EARTH BONDED.

1.6 TOTAL RATED HEAT INPUTS

Natural and Propane Gas

23kW (net) 86,300 btu/h (gross)

1.7 INJECTOR SIZES

Natural gas

Burner Pilot

2 x Ø2.7mm Polidora G31.2

Propane gas

Burner Pilot

2 x Ø1.7mm Polidora G25

SECTION 2 - ASSEMBLY and

COMMISSIONING

The gas supply piping and connection to appliance must

be installed in accordance with the various regulations

listed on the cover of this manual.

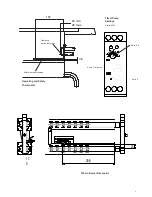

2.1 ASSEMBLY

a) Unpack appliance

b) Unpack fryer baskets and accessories.

c) Place basket support grid and basket in pan.

d) Level appliance and fit all service protection kits.

(Anti-tilt kit, if ordered as accessory).

2.2 CONNECTION TO A GAS SUPPLY

Connect gas supply and test for gas soundness.

Caution - Ensure that pan contains an acceptable level

of liquid before igniting burner.

Due to the presence of mains electrics, integral pipe work

should be checked for gas soundness using an

appropriate gas leak detector.

Caution - Installation engineers should note that for first

time connection of appliance to supply, it is essential that

inlet gas supply to fryer is completely purged of air prior

to first lighting attempt. Otherwise, since this is a light pilot

first every time system, it will take a significant number of

tries to light due to the small amount of air bled from pipe

by pilot at each attempt. This should not initially be treated

as a fault.

Please note that several attempts will still be required

after air purge to fryer for first time lighting. This is due to

capacity of valve and governor.

2.3 CONNECTION TO AN ELECTRICAL SUPPLY

Ensure flexible cable does not come into contact with any

hot parts. The fuse rating should be 13A.

The colour coding of power supply cables are as follows:

Live - Brown, Neutral - Blue, Earth - Green/Yellow

2.4 STARTING UP

If you are in the fat melting cycle (FMC – G401F only)

and loading solid fat for the first time, always remove

basket support plate as detailed in Section 9. Solid fat

should be in direct contact with fryer pan.

Refer to Section 9.

Содержание G402F

Страница 16: ...SECTION 11 WIRING DIAGRAM for G401 16...

Страница 17: ...SECTION 11 WIRING DIAGRAM for G401F 17...

Страница 18: ...SECTION 11 WIRING DIAGRAM for G402 18...

Страница 19: ...SECTION 11 WIRING DIAGRAM for G402F 19...

Страница 20: ...SECTION 11 CIRCUIT DIAGRAM for G401 20...

Страница 21: ...SECTION 11 CIRCUIT DIAGRAM for G401F 21...

Страница 22: ...SECTION 11 CIRCUIT DIAGRAM for G402 22...

Страница 23: ...SECTION 11 CIRCUIT DIAGRAM for G402F 23...