Page G-2

MOTOR & MOTOR BRAKE

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings.

B

.

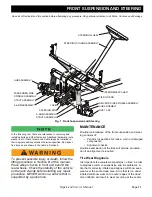

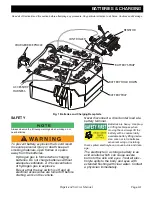

Fig. 2 Motor Connections

10. Pull the motor wires out through the bagwell.

11. Remove the six hex head bolts (2) and split lock wash-

ers (3) securing the motor (1) to the axle and carefully

slide the motor straight out from the axle splines.

Note: a drive belt or woven strap may be used as a

sling to help support the motor during removal.

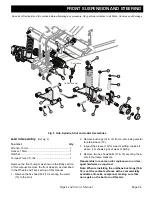

Fig. 3 Motor

12. Before installing the motor on the axle apply lubricant

(80% molybdenum disulfide paste) to the input shaft

spline.

The approved lubricants are: Dow Corning

77, Molykote (r) M-77 paste or Tribology TAS 100

EP

13. Carefully align the motor spline with the input shaft,

orient the motor with the wires near the top and install

the six hex head bolts (2) and split lock washers (3)

finger tight. Tighten the hex head bolts (2) in a cross

pattern to the specified torque.

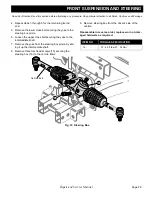

Fig. 4 Motor Bolt Tightening Sequence

14. Connect the wires from the main harness to the motor

brake, the motor sensor and the motor temperature

sensor.

15. Connect the wires from the motor to the controller; the

green wire to terminal U, the yellow wire to terminal V

and the blue wire to terminal W. Install the terminal

screws (27) finger tight, then torque as specified.

Do

not over tighten the terminal screws (27).

.

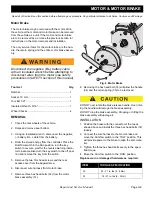

Fig. 5 Motor to Controller Connections

16. Connect the negative (-) battery cable, BL-, to the bat-

tery pack.

MOTOR

ITEM

TORQUE SPECIFICATION

2

53 - 79 in. lbs (6 - 9 Nm)

27

53 - 71 in. lbs (6 - 8Nm)