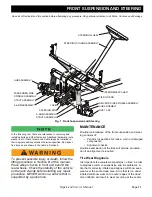

FRONT SUSPENSION AND STEERING

Page F-3

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings.

B

B

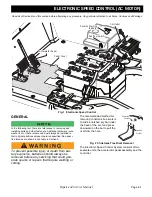

6. To adjust the wheel alignment, loosen the tie rod jam

nut (1) and turn the tie rods and equal number of turns

until the correct alignment is achieved.

Failure to turn

both tie rods the same number of turns will result

in poor turning radius.

7. Tighten the tie rod jam nuts (1) and torque as speci-

fied.

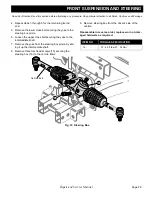

Fig. 4 Tie Rod Jam Nut

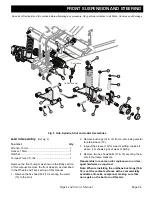

Hub Assembly

(Ref Fig. 5)

Tool List

Qty.

Socket, 24 mm ............................................................ 1

Ratchet........................................................................ 1

Torque Wrench, ft. lbs. ................................................ 1

Flat Blade Screwdriver ................................................ 1

Ball Peen Hammer ...................................................... 1

Remove the front wheel(s) as described in the Wheels

and Tires section of this manual.

1. Remove the dust cap (1) by tapping around the cap

flange using a flat blade screwdriver and a ball peen

hammer.

2. Remove the lock nut (2).

Note: it is recommended

that locking nuts be replaced after a maximum of 5

removals.

3. Remove hub (3) by sliding it off of the spindle.

4. Clean spindle (4) thoroughly with solvent and inspect

spindle threads; if threads are damaged replace the

spindle.

Reassemble parts in the reverse order, replace worn

or damaged hardware as required. It is recom-

mended that locking nuts be replaced after a maxi-

mum of 5 removals

Spindle Assembly

(Ref Fig. 5)

Tool List

Qty.

Wrench, 16 mm ...........................................................1

Socket, 16 mm.............................................................1

Socket, 18 mm Deep-well............................................1

Ratchet ........................................................................1

Torque Wrench, ft. lbs..................................................1

Ball Joint Separator .....................................................1

Ball Peen Hammer.......................................................1

Remove the front wheel(s) as described in the Wheels

and Tires section of this manual.

1. Remove the hub assembly as described in the previ-

ous section.

2. Loosen the nut securing the tie rod end to the spindle

arm until it is flush with the end of the tie rod end.

3. Using a ball joint separator as a lever, apply pressure

to the ball joint and tap the spindle arm sharply with

the hammer to release the tie rod end from the spindle

arm.

4. Remove the nut and the tie rod end from the spindle

arm.

5. Remove hex nut (9) and hex head bolt (8), remove the

spindle assembly (4 & 5).

Reassemble in reverse order, replace worn or dam-

aged hardware as required. It is recommended that

all locking nuts be replaced after a maximum of 5

removals

Check hex head bolt (8) before tightening, the head

of the bolt will show the grade or class (8.8 or 10.9),

be sure to tighten to the proper torque for the bolt

grade or class. For grade and class markings see

Fig. 7 on page A-4 of this manual.

.

ITEM

TORQUE SPECIFICATION

1

37 - 44 ft. lbs (50 - 60 Nm)

ITEM

TORQUE SPECIFICATION

2

90 - 96 ft. lbs (123 - 131 Nm)

ITEM

TORQUE SPECIFICATION

8 (class 8.8)

52 - 58 ft. lbs (70 - 78 Nm)

8 (class 10.9)

71 - 79 ft. lbs (96 - 107 Nm)