11 96VTR Ver. 2.0 11/99

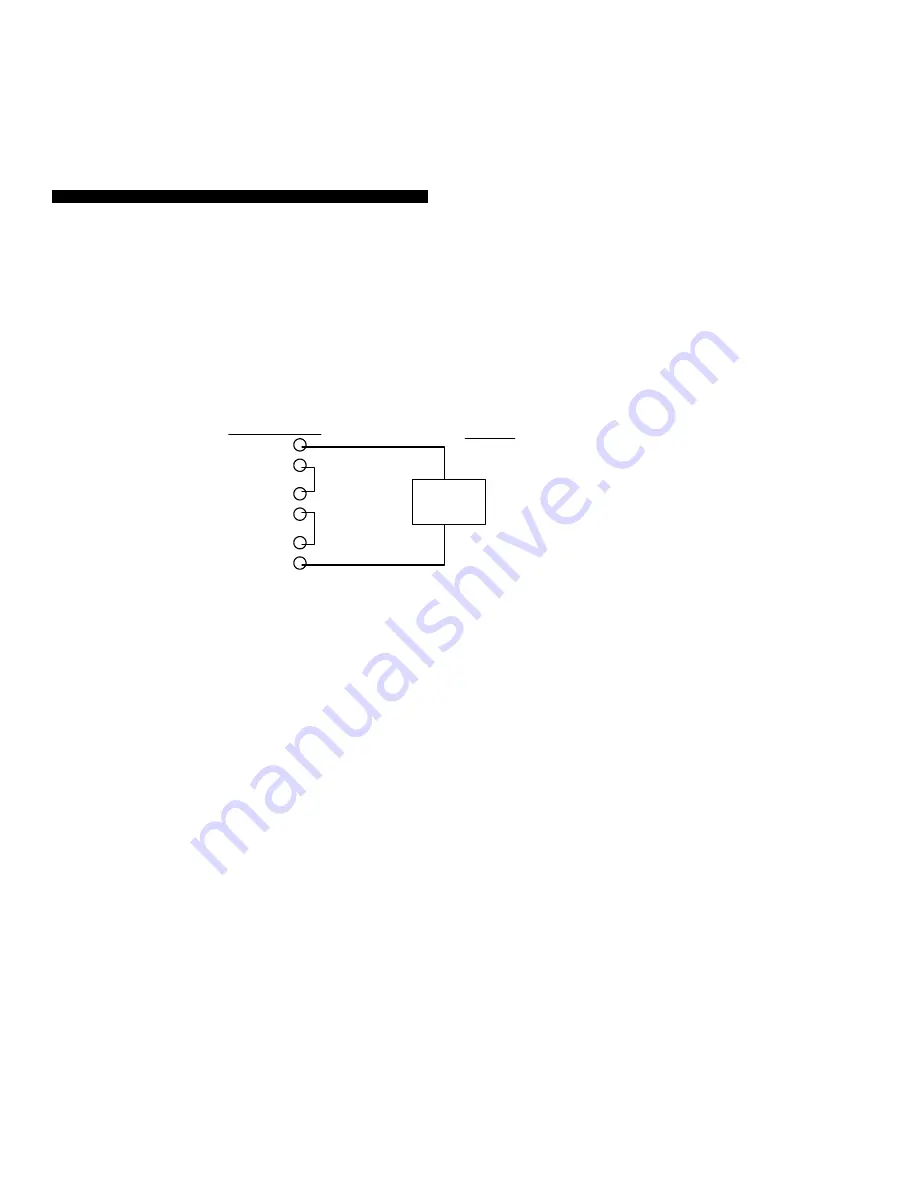

Control

Relay

Alarm

Relay

AC

Load

Example of Wiring Alarm and Control Relays in Series

Meter Contacts

Figure 4

16

18

12

13

19

20

The controller's output percent will now appear on the SV display preceded by an 'H"

for Heating or a 'C' for Cooling (depending upon how the action of the controller is

configured under the parameter 'act'). The 'MA' Manual status LED will also illuminate

and flash. To manually adjust the controller's output, use the UP and DOWN arrow

keys. For controllers using two control outputs (primary and secondary), the SV display

will automatically toggle between outputs 1 and 2. To return to normal operation, press

and hold the RETURN key until the 'MA' LED extinguishes. To Lock this feature, press

and hold the UP and RETURN keys until the display flashes. While locked, the Manual

Mode is inaccessible.

11. RAMP-TO-SETPOINT AND EVENT/SOAK TIMER FUNCTIONS

The Extech 96VTR controller operates as a fixed setpoint controller. However, the

controller offers several advanced features which can enhance your application. These

include Ramp-to-Setpoint and Event/Soak Alarm/Timers.

11.1 Ramp-to-Setpoint ('rAmP' Parameter)

To limit the rate at which the controller allows the process (PV) to move towards

setpoint (SV), enter a limit value in degrees (or other units) per minute in the 'rAmP'

parameter. The programmable limit ranges from 0.0 to 100.0 units per minute. The

controller will automatically adjust the controller's outputs to maintain the desired limit

programmed by the user. A setting of zero defeats the Ramp-to-Setpoint function.

11.2 Soak Timer Function (for use with Alarm 1 only)

The Alarm 1 Soak Timer allows the process to ramp to a setpoint and remain (Soak) at

that setpoint for a user-programmable period of time. Set the "A1Fu" parameter to

either '10' (Soak ON-TIMER) or '11' (Soak OFF-TIMER) depending upon the

application (See

Appendix A, Table

IV, for the

difference between

ON- and OFF-

TIMERS). Set the

Soak time in

parameter 'timE' in

the First

Programming Level.

The Output and

Alarm Relays must

be wired in series

so that the Alarm

relay can switch the control relay at the appropriate times (refer to Fig. 4). For

example, when a setpoint of 500

o

F is reached, the Soak time (programmed by the user

under parameter 'timE") begins to countdown. After the desired Soak time has elapsed,

the Alarm relay switches thereby switching the Control relay.

11.3 Event Timer (Alarm 1 relay only)

Alarm relay 1 can be programmed to switch state at desired times in a process. This is

accomplished by first setting the alarm function in parameter "A1Fu" to either an

EVENT-ON or EVENT-OFF Timer (See Appendix A, Table IV, for the difference

between ON- and OFF-TIMERS). Next, pick a count-down time. The relay timer will

start counting down once the PV equals the SV. The duration of the count-down is set

by the user at parameter "timE".

Application example: While maintaining a certain temperature for 4 hours, an event is

to take place 2 hours into the process. The event, in this example, is the controller's

alarm relay activating a pump. To do this, set the alarm function to an EVENT-ON