40

TROUBLE SHOOTING - SYMPTOM, CAUSE AND ACTION

(Continued)

SYMPTOM

CAUSE

ACTION

Arching in the steam

cylinder

An occasional arc is not a problem. When

a cylinder is restarted after a long period of

off time arcing may occur as pieces of mineral

flake off the electrode surface. During a drain

cycle, arcing may occur if water is very low in

the cylinder. Arcing is a problem if it occurs

frequently or if it causes dark brown or

red discoloration in the cylinder. The dark

deposits are caused by deterioration of electrode

material and must be prevented. Arcing may be

caused by several conditions:

Incoming water may have high conductivity.

Conductivity, the ability to conduct current, is

measured in “micromhos”. In any electrode

type humidifier there are maximum values of

conductivity that may be used in the humidifier. It

is very unusual for any naturally occurring water

to have conductivity that is too high for operation.

It is recommended that water conductivity be

less than 900 micromhos. If water is treated by a

water softener its conductivity will be higher than

untreated water. As it is boiled away its

conductivity also increases at a higher rate than

untreated water. Softened water may be too high

in conductivity to operate without arcing.

Drain lines within the humidifier that have become

restricted by mineral deposits prevent proper drain

rates. This causes minerals to concentrate inside

the cylinder, which in turn causes low water levels.

Low water levels cause arcing. Drain lines should

be inspected when cylinders are changed and

thoroughly cleaned if necessary.

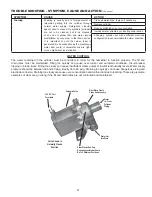

A defective drain solenoid valve will prevent proper

draining. The solenoid should be checked to verify

that it moves freely when 24VDC is applied to the

coil. When placed in the “Drain” position, both the

drain and fill valves open and it is very important

the water level falls in the cylinder.

Insufficient flow of incoming fresh water will cause

arcing by causing low water levels. Since an

automatic drain is not initiated until setpoint is

reached, a drain will not occur if the flow rate is

too low. Therefore, if low water pressure at the

humidifier (below 20 psi) or a clogged water

strainer restricts the flow of water, arcing will result.

High back pressure, which can be caused by an

obstruction in the steam hose, prevents fresh

water from entering the cylinder and results in

arcing. Care must be taken to prevent kinking of

steam hose when making bends.

Excessive lengths of steam hose in conjunction

with high duct static pressures cause low water

levels and arcing.

Frequent cleaning of the steam cylinder by

removing and flushing or by striking the side

of the cylinder potentially dislodges flakes that

can build up a “dam” in the drain lines. It is not

recommended that the cylinder be removed except

for replacement.

Chemicals should

never

be used to attempt

to prevent mineral build up in the cylinder or

to dissolve minerals that accumulate.

Chemical treatment may affect conductivity.

Only untreated tap water is recommended for

use in the humidifier.