20

OPERATION

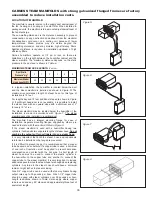

When the circuit board verifies all four basic controls have

been satisfied (control humidistat, high limit humidistat,

air flow, door interlock), a signal is sent to open a fill

solenoid valve, allowing water to flow across an air gap

into a standpipe. The standpipe provides a column of

water to be fed into the cylinder using gravity. The air gap

prevents the cylinder from pressurizing.

See Figure Q

.

The steam cylinder normally operates at a pressure of

approximately 1/2 psi.

STEAM

DISTRIBUTOR

PIPE

STEAM

HOSE

FROM POWER

CONTACTOR

CYLINDER

VERTICAL

ELECTRODES

DRAIN

SOLENOID

VALVE

TO DRAIN

STEAM

WATER

AIR GAP

FILL

SOLENOID VALVE

NON CONTACT

HIGH WATER

SENSOR

Figure Q

STAND

PIPE

OVERFLOW

TUBE

CONTROL CONNECTIONS

FOR SAFETY:

MAKE SURE TO TURN OFF POWER AT THE

EXTERNAL DISCONNECT BEFORE MAKING ANY INTERNAL

CHANGES TO THE HUMIDIFIER.

1. A 7/8” opening is provided on the top or bottom of the cabinet.

The control wiring should pass through the opening to the

provided connection points at J16, J17, and J18.

2. If an air flow switch or high limit humidistat is not used,

jumpers must be installed before the humidifier will operate.

On J17, jump terminals 2 and 4 together to bypass the high

limit. On J18, jump terminals 1 and 2 together to bypass the

air flow switch.

EXTERNAL MONITORING

Pins 1 and 2 of connector J10, shown in

Photo H

, are provided for

indicating operation of the humidifier at a remote location. When

the unit is operating, pins 1 and 2 (EXT PWR) are closed. Pins

3 and 4 of connector J10 (EXT SRV) are provided to indicate

the need for service. A “Service Required” warning on the home

screen of the LCD will indicate the type of service that is needed.

Both the EXT PWR and EXT SRV relays have a maximum ratings

of 0.3A at 125VAC or 1A at 24VDC maximum.

CarnesLink is an option to have full external monitoring and

control of your Carnes humidifier(s) by allowing the humidifier(s)

to link to a Building Management System (BMS) using one of the

following protocols: BACnet® (MS/TP), Modbus® (RTU),

Metasys® (N2) and Siemens® (FLN).The user friendly interface

on the True Touchscreen makes setting up CarnesLink easy

and convenient. (See the CarnesLink Communication Protocol

Installaion, Operation, and Maintenance Manual for further info.)

NETWORKING

If multiple units are required due to high capacity demand

(over 200 lb. per hour, single unit), networking can be done.

Units can be interconnected with parallel signal wiring. This setup

is usually done to facilitate running multiple units from a single

signal control (Humidistat, BMS System, etc.). For other

networking requirements, please contact factory.

As mineral deposits build up within the cylinder the water

level will slowly rise to uncovered electrode surfaces to

maintain the desired steam output rate. When mineral

deposits have covered all available electrode surfaces,

current flow will be reduced to a level where the desired

steam output cannot be reached and the service light will

signal the need for maintenance. When the cylinder is filled

with minerals it is easily changed in less than five minutes

(not including cool down time).

Important Note:

Due to the many variables effecting the

operation of humidifiers (water condition, conductivity,

hardness, etc.) it could take up to 24 hours of operation

before a humidifier is truly operating normally and the water

is completely conditioned. Conditioned water is a state

where the amount of minerals dissolved within the water

is at a steady state. Conditioned water is more conductive

than new water from the fill valve.

The circuit board also closes a power contactor allowing

current to flow to vertical electrodes sealed inside the

cylinder. Current flows between the electrodes using

minerals in the water as a conductor. The water is heated

to boiling and converted to steam which leaves the cylinder

through the flexible steam hose which is connected to the

steam distributor pipe.

The circuit board reacts to current flow between the

electrodes and automatically opens the fill solenoid valve

when more water is required to maintain the desired

output rate and closes when the desired rate is reached.

The operation of the drain solenoid valve is automatically

controlled by the circuit board which responds to any

changes in water conditions and drains the required

quantity of water to provide stable operation and long

cylinder life.

Photo H