Maintenance

Important:

After all neutral adjustments have

been made, make sure the drive wheels have

equal speed in the full forward and reverse

positions.

Tracking Adjustment

1. Stop engine and wait for all moving parts to stop.

2. Check the drive tire pressures and tire

circumferences as stated in

Check the Tire

Pressures

section in Maintenance.

3. Run the unit and observe the tracking on a level,

smooth, hard surface such as concrete or asphalt.

4. If the unit tracks to one side or the other, turn the

quick track knob. Turn the knob right to “steer”

right, turn the knob left to “steer” left.

Drive Lever Resistance

Adjustment

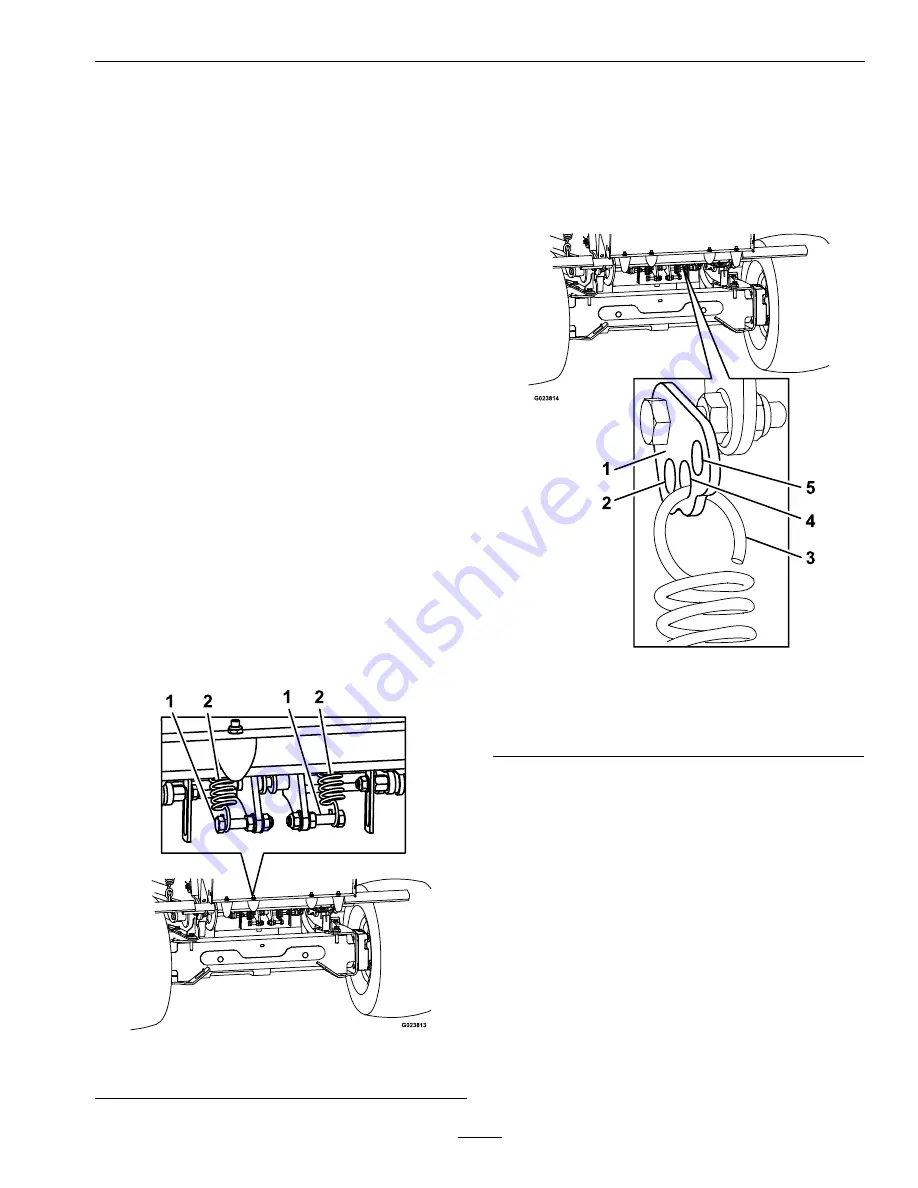

Relocating the hydro pump springs to a different

setting will change the resistance on the drive levers.

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Raise the platform.

3. Unhook both springs from the lower bellcrank

bolts (see Figure 38).

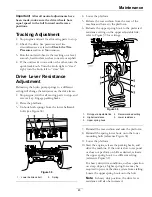

Figure 38

1.

Lower bellcrank bolt

2.

Spring

4. Lower the platform.

5. Release the rear cushion from the rear of the

machine and lower to the platform.

6. Relocate the upper spring hook to the preferred

resistance setting on the upper adjustable link;

refer to Figure 39 for settings.

Figure 39

1.

RH upper adjustable link

4.

Recommended setting

2.

Higher resistance

5.

Lower resistance

3.

Upper spring hook

7. Reinstall the rear cushion and raise the platform.

8. Reinstall the spring lower hook onto the lower

mounting bolts (reference Figure 38).

9. Lower the platform.

10. Start the engine, release the parking brake, and

drive the machine. If the unit is slow to respond

or does not perform on hills as desired, relocate

the upper spring hook to a different setting

(reference Figure 39).

For heavy duty drive conditions, such as operation

on steep slopes, a higher spring force may be

required to prevent the drive system from stalling.

Locate the upper spring hook onto the bolt.

Note:

In heavy duty position, the drive lever

resistance will also be increased.

45

Содержание VANTAGE X Series

Страница 1: ...VANTAGE X SERIES For Serial Nos 315 000 000 Higher Part No 4502 224 Rev A ...

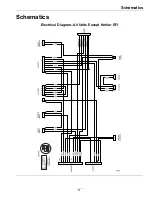

Страница 51: ...Schematics Schematics Electrical Diagram All Units Except Kohler EFI 51 ...

Страница 52: ...Schematics Electrical Diagram Kohler EFI 52 ...

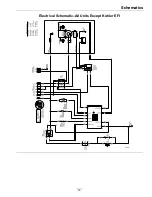

Страница 53: ...Schematics Electrical Schematic All Units Except Kohler EFI 53 ...

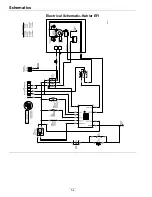

Страница 54: ...Schematics Electrical Schematic Kohler EFI 54 ...

Страница 55: ...Schematics Hydraulic Diagram 55 ...

Страница 57: ...Service Record Date Description of Work Done Service Done By 57 ...

Страница 58: ...58 ...