Pellet store

Requirements for pellet store

35

boards must be mounted on the inner wall (30 mm

thick with tongue and groove) so the pellets cannot

push against the door, or so that it can be opened.

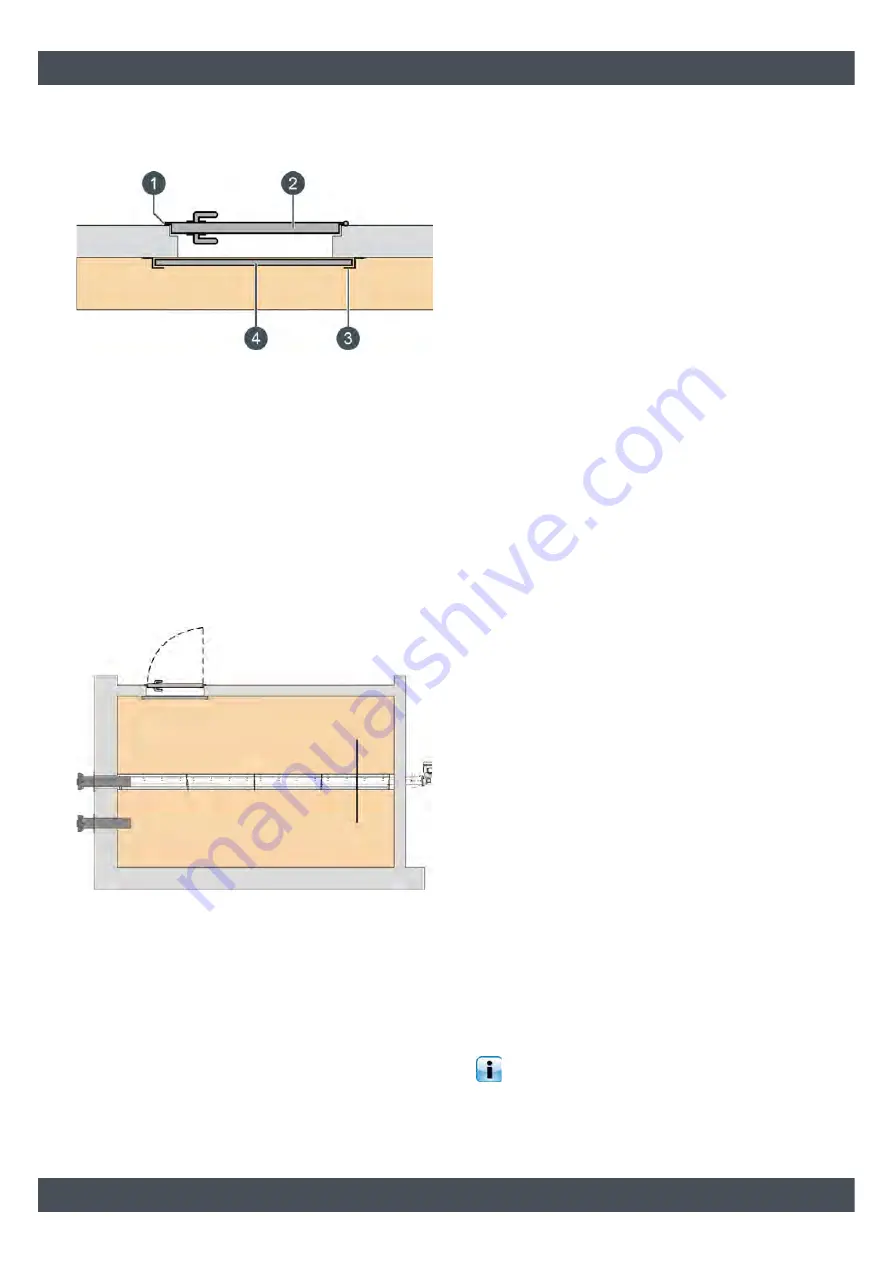

1

Seal between door and frame

2

Fire-resistant door

3

Z profile for boards

4

Boards

The door's lock must be sealed against dust on the

inner side. In spite of a widely circulated construction

document, the door handle on the inner side may not

be removed. It must be possible to open the door from

the inside in an emergency.

For screw conveyors, the store room door should be

positioned on the opposite side to the screw drive.

Because this area of the store empties first and, if

required, facilitates quick access to the store.

Electrical socket for pellet supplier's blower

For the pellet supplier's suction blower, a 230 V

electrical socket (C-13A fuse) in the vicinity of the filling

nozzle is useful.

6.2

Requirements for pellet store

Structural requirements

The pellet store's walls must withstand the load caused

by the weight of the pellets (bulk weight 650 kg/m³).

The plasterwork should also be durable enough that it

cannot rub or flake off and contaminate the pellets.

If the forces from the tilted floor construction are

directed into the floor and not the wall, then the

following wall thicknesses have proven effective in

practice given proper anchoring in the enclosing

masonry:

•

Concrete 100 mm thick.

•

Common brick 170 mm thick and plastered on

both sides.

•

Post-and-beam walls with 120 mm beams,

clearance 625 mm, with wooden panelling 15-

20 mm thick on both sides.

Dry storage for pellets

Pellets are very hygroscopic; they absorb moisture

from the environment. On contact with water or moist

walls, they swell up and break apart, becoming

unusable.

The pellet store must stay dry throughout the year. The

normal humidity encountered in normal residential

construction throughout the year is not harmful to the

pellets.

If there is a danger of moist walls from time to time,

such as in older buildings, we recommend installing

rear-ventilated wood facing on the walls or storing the

pellets in a fabric silo.

Regularly remove the dust from the pellet store

The pellet store must be regularly "emptied", so that

the dust can be removed from the pellet store.

Because the pellets "crumble" after a few years and

produce dust. In combination with increased air humid-

ity, this dust can lead to blockages of the suction

probes or prevent the pellets from sliding on the

slanted floor in the storeroom.

An increased amount of dust often occurs in oversized

storerooms that are only filled every 2 - 3 years,

because the high bulk weight of the pellets slowly

crushes the pellets below. Even in storerooms with

suction probes without inclined floor, "old" pellets often

remain between the suction probes and then crumble

slowly.

Therefore, the pellet store must be "emptied" at

the latest every three years, so that the dust can

be removed before refilling. Shovel "old" pellets either

to the discharge screw or the suction probe, so that

they are quickly used up.

Содержание 11120L

Страница 1: ...2020 07 21 EN 0000000371 V 012 2503 939023 004 TWIN pellet burner 40 50 kW Installation...

Страница 7: ...General Dismantling disposal 7...

Страница 27: ...Installation Network connection 27...

Страница 47: ......

Страница 48: ...www eta co at www eta co at downloads DOWNLOAD...