11

EST 246

regulation wheel. By turning to the left, the supplied volume of air

is increased and the beam is spread.

r

egulation

of

the

air

supply

into

the

sprayer

This regulation (17) is located in the upper

axis of the sprayer and enables throttling of the

supplied volume of air into the sprayer by which

the operator may decrease the volume of air for

spraying without the necessity to change on the

air regulator in the distribution system.

r

epracement

of

the

nozzle

system

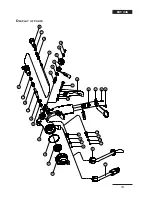

After dismantling the stop bolt (20) remove the spring for the

needle (18) with the bearing (19) and the needle (2). For easier

manipulation, press the lever which pushes out the needle from

the rear part of the sprayer. Remove the nozzle (1) from the front

part by unscrewing. Dismantle the nozzle from the sprayer by the

attached wrench (41). Before assembly of a new nozzle system,

it is recommended to clean the assembly areas. Attach the new

nozzle and fully tighten. The recommended tightening moment on

the nozzle is 10 Nm. On the rear part, insert the needle with the

spring and attach the stop bolt with the nozzle.

r

eplacement

of

the

needle

seal

In the case of leaks, it is necessary to

tighten the seal (29) using the bolt on the

seal (32) turn the bolt in a clockwise direction

into the position where the seal tightens

again. In the case that it is not possible to

turn the bolt on the seal and the seal does

not tighten, it is necessary to replace the seal

with new. Unscrew the bolt on the seal (32)

and remove the set of the old seal. Before

the insertion of a new seal, clean the area

for the seal. Insert a new seal (29), guiding

of the spring (30) and spring of the seal (31) from the set of the

needle sealing. Tighten the bolt of the seal so that the seal reliably

tightens. The seal on the enamel is replaced similarly.

r

eplacement

of

tightening

the

air

ValVe

»

demontáž: (fig a) Dismantle the stop bolt (20) with the spring

(18) and the needle (2). Using the wrench (41) dismantle the

air regulation (17) with the spring (16) from the sprayer. Insert

by pressing the level of the cone (15) into the sprayer, insert

the assembly drift (36) from the air valve set, insert the needle

and push out sealing U1 (13) from the sprayer by pressing the

lever. The sealing will remain on the code which you consequently

29

30

31

32

Содержание 246

Страница 23: ...23 EST 246 ...