37

TROUBLESHOOTING GUIDE - (Cont)

WELD CONDITION

POSSIBLE CAUSE

REMEDY

10. Shield gas flow low or

a. Cylinder valve closed.

a. Turn off regulator, slowly open

stopped.

valve, until regulator reaches

35 c.f.h. pressure.

b. Cylinder empty.

b. Replace if gauge so indicates.

c. Faulty regulator or adaptor.

c. Check flow at outlet; replace

faulty item.

d. Faulty gas solenoid valve.

d. Replace solenoid valve.

11. Wire stubs on work

a. Controls not set properly for

a. Reset controls properly.

while welding.

metal gauge, thickness.

12. Wire burns back into

a. Contact tip loose.

a. Firmly tighten with pliers.

contact tip.

b. Tip too close to work.

b. Maintain 1/4" (.6 cm) wire

protrusion; hold torch further

from work.

c. Wire feed slipping.

c. Increase pressure on pressure

roll by adjusting pressure knob.

d. Contact tip damaged.

d. Trim back tip 1/16" (1.6 cm) max.

Replace if still faulty.

e. Voltage setting too high.

e. Adjust setting.

f. Drive or pressure roll dirty or

f.

Clean rolls or replace.

worn.

13. Wire does not feed;

a. Kink, etc. in wire, or wire bound

a. Straighten; or feed wire until

motor running (drive

on reel.

clear and cut off.

roll turns).

b. Wire freezing to contact tip

b. Free freeze, or remove contact

(burnback).

tip feed wire until clear cut end

free, and replace tip.

c. Clogged liner.

c. Replace liner.

14. Wire does not feed;

a. Motor.

a. With wire speed dial on 10,

motor NOT running

press trigger. If voltage

(drive roll does not turn).

appears across motor leads

but motor does not run, check

motor gears and commutator

areas.

b. Power switch S1 and CB1.

b. With S1 ON, if voltage across

terminal 1 and 3 is 24 V ac,

switch and fuses are good.

c. Defective PCB1.

c. Check board voltages

(Para. 7.1.1).

15. Wire feed does not stop.

a. Torch trigger switch.

a. Check continuity of torch trigger

circuit; check to see if trigger

lever is stuck in "ON" position.

b. PCB1.

b. Check for proper action.

16. Gas continues to flow

a. Gas solenoid valve stuck open.

a. Tap solenoid or click on and off

after trigger release.

to clear valve.

Содержание Migmaster 300i cvcc

Страница 38: ...38...

Страница 39: ...39...

Страница 40: ...40...

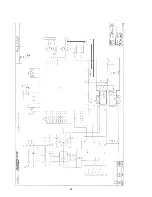

Страница 46: ...46 2 3 4 5 6 7 8 9 10 11 12 13 14 15 1 16 17 18 19 20 21 FIGURE 8 3 MIGMASTER 300i RIGHT INTERIOR VIEW...