16

The MigMaster 300i is capable of MIG, TIG, and STICK

welding processes. It is designed to connect and dis-

connect a MIG Torch, TIG Torch, and a STICK elec-

trode holder quickly and safely.

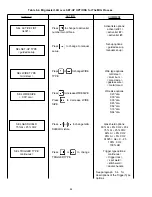

As shown in Figure 4-3, the MigMaster 300i has posi-

tive (J5) and negative (J6) ELECTRODE output recep-

tacles for output power.

The torch polarity cable is hardwired internally to torch

connector receptacle J4 (located in wire feed compart-

ment). This internal connection and the ELECTRODE

receptacle (- or +) that the torch polarity cable plug

(P12) is connected to, determine the welding polarity.

For example; by connecting P12 to the negative (-)

ELECTRODE output receptacle (J6), the torch con-

nected at J4 will be welding with straight dc polarity.

By connecting P12 to the positive (+) ELECTRODE

output receptacle (J5), the torch will be welding with

reverse dc polarity. The latter polarity (reverse) is the

most commonly used way to weld with the MIG pro-

cess.

4.5 WELDING CABLE CONNECTIONS (WORK

CABLE)

Connect the plug of the work cable to the ELECTRODE

output connector not being used. Connect the work

clamp solidly to the workpiece on work table. Clamp

onto a bare metal area.

A GOOD ELECTRICAL CONNECTION TO THE

WORK IS ESSENTIAL TO PROPER WELDING OP-

ERATION AND TO PREVENT ELECTRIC SHOCK.

Welding cables should be kept as short as possible

and be of adequate current carrying capacity. Resis-

tance of the welding cables and connections causes a

voltage drop which is added to the voltage drop of the

arc. Excessive cable resistance may result in a re-

direction of the maximum usable current output of the

equipment.

The proper operation of this equipment is to a large

extent dependent on the use of welding cables and

connections which are in good condition and of ad-

equate size.

4.6 INSTALLATION FOR MIG WELDING

BE SURE THE BRANCH CIRCUIT OR MAIN DIS-

CONNECT SWITCH AND MIGMASTER POWER

SWITCH (FIGURE 4-3) IS OFF OR ELECTRICAL

INPUT CIRCUIT FUSES ARE REMOVED BEFORE

MAKING OR CHANGING SECONDARY CONNEC-

TIONS ON THE MIGMASTER 300i. BE SURE THAT

WIRE AND/OR TORCH IS NOT TOUCHING

WORKPIECE WHEN INITIALLY APPLYING POWER.

4.6.1 TORCH CONNECTION (MT-200CC)

The MT-200cc Torch is supplied as standard equip-

ment with the MigMaster 300i Power Source.

To connect the MT-200cc Torch to the Power Source,

line up the connector of the torch cable with matching

holes in Power Source connector receptacle J4 (Fig-

ure 4-3). Insert torch cable plug and tighten the lock-

ing collar.

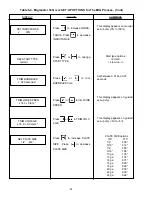

4.6.2 TORCH POLARITY CABLE AND WORK

CABLE (FIGURE 4-4)

For welding mild steel, stainless steel, and aluminum

using cored wires, connect plug P12 to the ELEC-

TRODE positive (+) output receptacle (J5) on Power

Source. Connect the work cable plug to the ELEC-

TRODE negative (-) output receptacle (J6) as described

in paragraph 4.5. The connection setup described will

give dc reverse polarity welding. In addition to Figure

4-4, refer to the MIG connection illustration on the front

of the Power Source in the MIG block.

Figure 4-4. MIG Connections

For some cored wires the torch needs to be connected

for straight dc polarity welding. To make this connec-

tion setup, connect plug P12 to the ELECTRODE nega-

tive (-) output receptacle (J6) and the work cable plug

to the ELECTRODE positive (+) output receptacle (J5)

as described in paragraph 4.5. After making the de-

sired polarity welding connections, place Process Se-

lector Switch (Figure 4-3) to the MIG position. Refer to

Section V for operational instructions.

J6

P12

J5

J6

P12

J5

Содержание Migmaster 300i cvcc

Страница 38: ...38...

Страница 39: ...39...

Страница 40: ...40...

Страница 46: ...46 2 3 4 5 6 7 8 9 10 11 12 13 14 15 1 16 17 18 19 20 21 FIGURE 8 3 MIGMASTER 300i RIGHT INTERIOR VIEW...