21

V. SETUP AND USAGE OF MIGMASTER

300i

5.1 CONTROLS

5.1.1 POWER SWITCH

The rotary power switch is located on the back panel

in the upper right hand corner. This switch also turns

on the fan. The twelve o'clock position is the OFF po-

sition, the ON is one quarter turn clockwise.

5.1.2 PROCESS SELECTOR SWITCH

The three-position process selector switch is on the

upper right front panel. The processor selector switch

provides the visual indication of which process (MIG,

TIG, or STICK) has been selected.

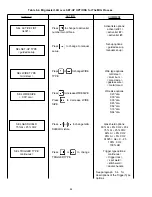

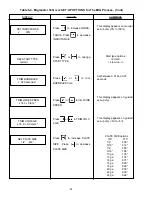

5.1.3 CONTROL DISPLAY SCREEN (Figure 5-1)

Welding setup options are controlled and monitored

by use of the Display Window and the control

pushbuttons. The screen displays the settings required

for the desired welding process as determined by the

position of the Process Selector Switch. The Scroll

Key is used to select functions as required to select

wire speed, voltage, trigger type, etc. The arrow keys

are used to select options. For example, the operator

would use the keys in order to select plate size. The

scroll key is depressed several times, until SEL PLATE

SIZE is displayed. The arrow keys are then depressed

until the desired plate size appears in the display.

Figure 5-1. Control Display Screen

5.1.4 SECONDARY WELDING CONNEC-TIONS

The secondary output welding terminals, POS (+) and

NEG (-), are located on the lower front panel directly

beneath the torch connector J4 (see Figure 4-3).

5.2 OPERATING PROCEDURES

5.2.1 OPERATING SAFETY PRECAUTIONS

COMPLY WITH ALL VENTILATION, FIRE AND

OTHER SAFETY REQUIREMENTS FOR ARC

WELDING AS ESTABLISHED IN THE SAFETY SEC-

TION AT THE FRONT OF THIS MANUAL.

Also remember the following:

A.

Because of the radiant energy of the welding

arc and the possibility of drawing an arc before

the helmet is lowered over the face, the opera-

tor should wear flash goggles with filter lenses

under his helmet. The helmet filter plate should

be shade number 11 (nonferrous) or 12 (fer-

rous). All those viewing the arc should use

helmets with filter plates, as well as flash

goggles. Nearby personnel should wear flash

goggles.

B.

The radiant energy of the arc can decompose

chlorinated solvent vapors, such as trichloro-

ethylene and perchloroethylene to form phos-

gene, even when these vapors are present in

low concentrations. DO NOT weld where

chlorinated solvents are present in atmo-

spheres in or around the arc.

C.

DO NOT touch the electrode, nozzle or metal

parts in contact with them when power is on; all

are electrically energized (HOT) and can cause

a potentially fatal shock. DO NOT allow elec-

trode to touch grounded metal, it will create an

arc flash that can injure eyes. It may also start

a fire or cause other damage.

D.

When working in a confined space, be sure it

is safe to enter. The confined space should be

tested for adequate oxygen (at least 19%) with

an approved oxygen measuring instrument.

The space should not contain toxic concentra-

tions of fumes or gases. If this cannot be

determined, the operator should wear an ap-

proved air supplied breathing apparatus. DO

NOT bring gas cylinders into confined spaces.

When leaving a confined space, shut off gas

supply at the source to prevent gas from leak-

ing into the confined space.

E.

Never operate the equipment at currents greater

than the rated ampere capacity; overheating

will result.

F.

Never operate equipment in a damp or wet

area without suitable insulation for protection

against shock. Keep hands, feet and clothing

dry at all times.

G.

Whenever the equipment is left unattended,

turn all control and power supply switches and

gas supplies off and open the main line switch.

H.

Wear dark substantial clothing to protect ex-

posed skin from arc burn, sparks and flying hot

metal.

Содержание Migmaster 300i cvcc

Страница 38: ...38...

Страница 39: ...39...

Страница 40: ...40...

Страница 46: ...46 2 3 4 5 6 7 8 9 10 11 12 13 14 15 1 16 17 18 19 20 21 FIGURE 8 3 MIGMASTER 300i RIGHT INTERIOR VIEW...