12

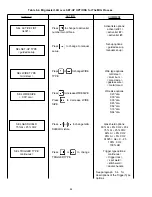

3.4 FINDING WELDING PARAMETERS IN MIG

For MIG welding, the MigMaster 300i offers two meth-

ods of setting the welding conditions. The initial

SELection is made when SEL SET-UP TYPE is pre-

sented on the upper line of the display. The two meth-

ods are: guided mode and manual mode.

The "manual mode" gives the same function as con-

ventional MIG welding equipment. It allows the set-

ting of voltage, wire feed speed, and inductance. This

requires prior knowledge by the operator to know what

to set for the job being performed.

In case the operator does not know what voltage and

wire feed speed to use for the job, he may use the

"guided mode". This mode contains a built-in table

that when given wire type and size, shielding gas, and

plate size, it calculates a good starting point for wire

feed speed and voltage. From this starting point, the

operator can deviate with the TRIM line for voltage

and wire feed speed. The TRIM lines on the display

show actual values and how far from the preset val-

ues the operator has moved the actual value.

The voltage is trimmed up for longer arc length and

down for shorter arc length. Wire feed speed is

TRIMmed up for more wire feed speed and current. If

wire feed speed is TRIMmed down, the reverse will

occur. Using these two trims, it is possible for the

operator to find the ideal parameters for the job.

When wire feed speed is trimmed, the voltage is

changed on the basis of a relationship that is stored in

the control logic. This is made to maintain a constant

arc length with a change in wire feed speed to make

the effort of finding a parameter combination for the

job easier. This relationship and the combined change

is referred to as a synergic function. Refer to para-

graph 3.5.

3.5

SYNERGIC RELATIONSHIPS AND

FUNCTIONS

The selection of material is done to help the operator

set up the Power Source for operating in MIG. By de-

fining the welding consumables to be used and the

size of material to be welded, the operator receives

help from the control unit to set the welding param-

eters. The wire speed and welding voltage is preset

by the control unit as a function of the chosen

consumables and material size.

Setting of the plate thickness will have the same effect

as a coarse setting of wire feed speed. The relation-

ship between them is determined by the consumable

selection process above.

The relationships are set up as tables of wire feed speed

being a function of plate size and linear relations be-

tween wire feed speed and voltage. The relationships

will in most cases cover the short arc or the spray arc

made in MIG welding. For wire types and shielding

gases that cover both material transfer types, a switch

is made one plate size (wire feed speed) when the wire

feed speed increases and another (lower) when it is

decreased. The switch will make a change in voltage

to accommodate the change from short arc to spray

arc.

In recognizing that it is impossible to preset welding

equipment to match all possible joint configurations and

welding positions, there are two ways to fine tune the

setting: 1) With the decrease/increase keypads,

change the wire feed speed or offset the precalculated

voltage or 2) perform the same function using the re-

mote control knobs in the torch or on the pendant.

If the parameters have been set up in "guided mode"

and the SEL SET-UP TYPE is changed to "manual

mode", the voltage and wire feed speed settings, at

that time, are moved over to the manual setting of volt-

age and wire feed speed.

3.6 SERVO FUNCTIONS

Changes in the stick out of the torch on a conventional

welding power source will cause a change in welding

voltage. This is compensated for by the servo function

of the MigMaster 300i.

When the MigMaster 300i is set to a specific voltage

(in MIG), the arc voltage is monitored and maintained

by a voltage servo on the control electronics board. A

similar servo operates when the MigMaster 300i is used

for STICK welding. In this case, the welding current is

monitored and maintained to the preset value. A con-

ventional power source for STICK changes the cur-

rent when the arc length is changed.

These two servos are designed to not interfere with

the necessary "slopes" and "inductances" that are

needed for the MIG and STICK welding processes.

Содержание Migmaster 300i cvcc

Страница 38: ...38...

Страница 39: ...39...

Страница 40: ...40...

Страница 46: ...46 2 3 4 5 6 7 8 9 10 11 12 13 14 15 1 16 17 18 19 20 21 FIGURE 8 3 MIGMASTER 300i RIGHT INTERIOR VIEW...