Sump Cleaner

17

1. Before operating this equipment for the first time,

and periodically thereafter, review the SAFETY

INFORMATION beginning on page three of

this manual.

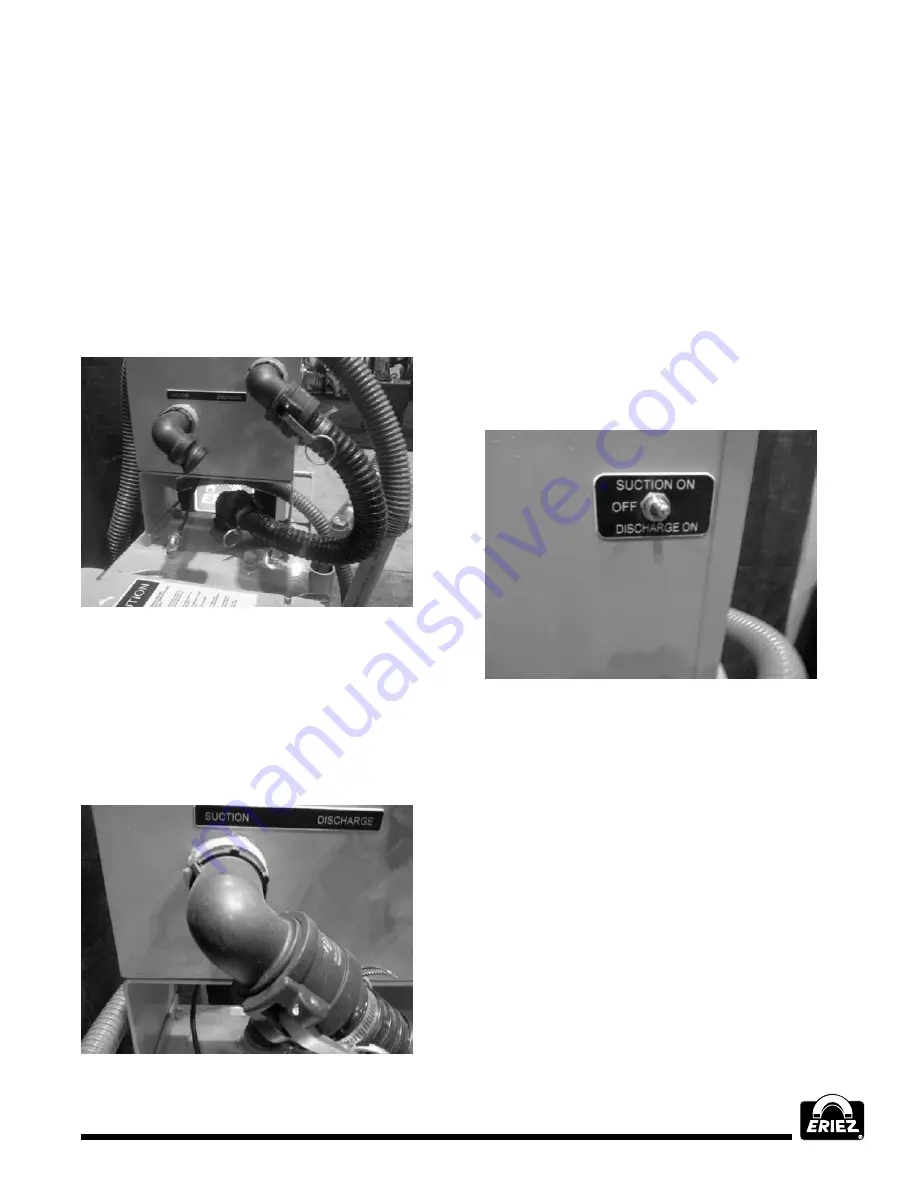

2. Suction vacuum and discharge pressure are

applied independently in this unit by moving a

hose attached to the tank to either the suction

fitting or the discharge fitting to the powerhead

enclosure as required.

120V Electric Models

Operation

B. Open suction inlet valve fully with suction

hose properly attached. MAKE SURE THAT

THIS VALVE IS EITHER FULLY OPEN OR

FULLY CLOSED AT ALL TIMES. FAILURE

TO DO SO WILL ALLOW PARTICULATE

MATTER TO ENTER THE VALVE SEAT,

WHICH COULD SEIZE THE VALVE.

C. Make sure that the discharge hose is

connected, and that the discharge nozzle

is attached and closed.

D. Turn on the Sump Cleaner by placing the

“on-off-on” switch into the “SUCTION ON”

position.

NOTE

: THE FLOAT SWITCH

WILL ONLY WORK WHEN “SUCTION ON”

IS SELECTED. IT IS NOT WIRED INTO THE

“DISCHARGE ON” CIRCUIT.

3. Connect the Sump Cleaner to the electrical

supply specified on the electrical box housing

the motor. For North America, this is 120 VAC,

single phase, 60 Hz.

4. Suction Operation:

A. Connect the black hose to the suction

port on the electrical box containing the

motor assembly.

E. Vacuum coolant, chips, and sludge from

the machine sump.

F. An electric float located in the tank will rise

with the rising liquid level in the tank and shut

off the motor when the tank is full. When this

occurs, the Sump Cleaner will stop.

G. When you are done vacuuming coolant and

chips, turn off the Sump Cleaner.

5. Discharge Operation:

To return filtered,

chip-free coolant to the machine, to wash down

the machine, or to discharge coolant into your

recycling or disposal system:

A. Close the suction inlet valve completely.

B. Move the black hose from the suction inlet

(on the electrical box housing the motor

assembly) to the discharge fitting.

Содержание FJ-310A

Страница 27: ...Sump Cleaner 27...