Sump Cleaner

9

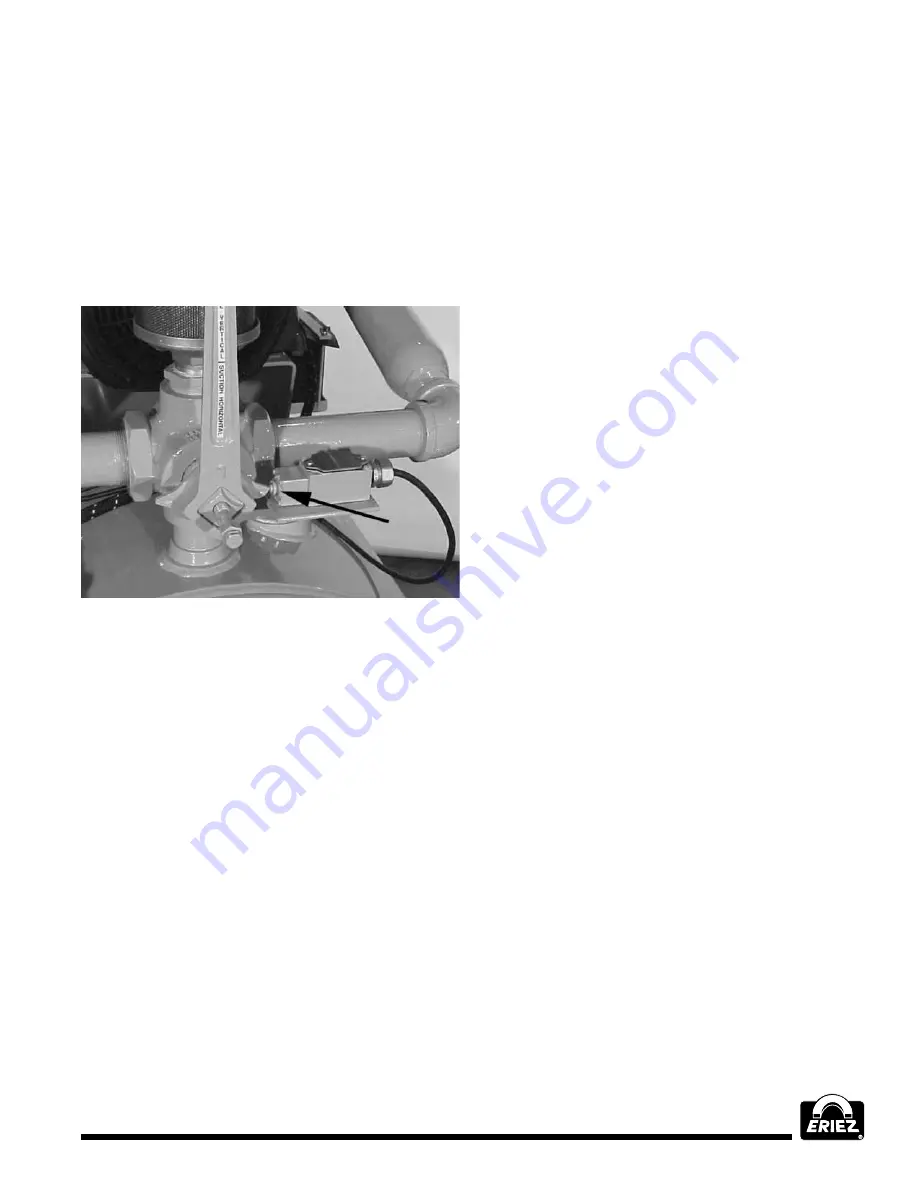

A. THE SUCTION/DISCHARGE lever must

be turned its full quarter turn to the vertical

(DISCHARGE) position in order to close a

limit switch beneath the lever (FIGURE 5).

This limit switch bypasses the float switch

needed to prevent overfilling during the

suction operation, but is not required for

discharge operation. The engine won’t start

in the discharge mode if sump cleaner tank

is full and the limit switch is not closed.

FIGuRE 5

Limit switch under the suction/discharge lever

B. Be sure the suction inlet ball valve is fully

closed before operating in the discharge mode.

C.

IMpORTANT!

Be sure the suction inlet ball

valve is fully closed or fully open, depending

on the desired operation (closed-discharge,

open-suction). Failure to do so will allow

particulate to enter the valve seat and

seize the valve.

8. When fluid stops passing through the hose,

release pressure by shifting the SUCTION/

DISCHARGE lever to the horizontal (SUCTION)

position. This must be done before opening the

inlet ball valve or removing tank lid, cleanout door

or drain plug. The engine will momentarily “SPEED

UP” and then “SLOW DOWN” and begin to

“labor”. Once the engine has begun to labor, the

engine may be switched OFF. Open the ball valve

and turn OFF the gas bottle valve.

9. The cleaner will discharge all but about an inch

of fluid in the bottom of the compartment. This is

unimportant if the compartment is used for one

type of coolant only. If different coolants are

involved, remove the compartment’s drain plug

to empty it completely. Replace drain plug after

emptying.

10. To empty the filter basket

:

A. Remove tower lid.

B. Attach lifting device to basket rings.

CAuTION:

All components used to lift basket

(steel cable, hooks, crane, etc.) must have a

minimum capacity of 1000 pounds.

C. To avoid the basket binding in the tower

during removal, position the lifting power

source (e.g. crane) directly over the center

of the basket.

D. Hoist the basket. Keep hands and fingers

clear. If the basket is binding and unable to lift

freely, return (lower) the basket to the sump

cleaner tower. Reposition the lifting device so

that the basket exits the center of the tower.

E.

DO NOT TOuCH BASKET DuRING

REMOVAl.

F. Position the basket over the waste receptacle.

G. Standing clear, open the basket trapdoor by

pulling the locking pin cable.

H. Once the basket is empty, carefully close the

trapdoor and slide the locking pin into place.

I. Check the filter sleeve. If it is badly soiled

or clogged, turn it inside out and wash it

in a suitable cleaner. Replace filter when

necessary. (Refer to the MAINTENANCE

section of this manual.)

J. Inspect the basket hoisting rings for signs

of rust. Replace the basket with a new one

if the rings are heavily corroded.

K. Keeping hands and fingers from under the

basket lip, reseat the basket in the tank and

clamp down the tank lid.

Содержание FJ-310A

Страница 27: ...Sump Cleaner 27...