Code: I.H4.V10.3003

Installation and Maintenance Manual

Version: 07

42 / 66

Ennera Energy and Mobility, S.L.

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

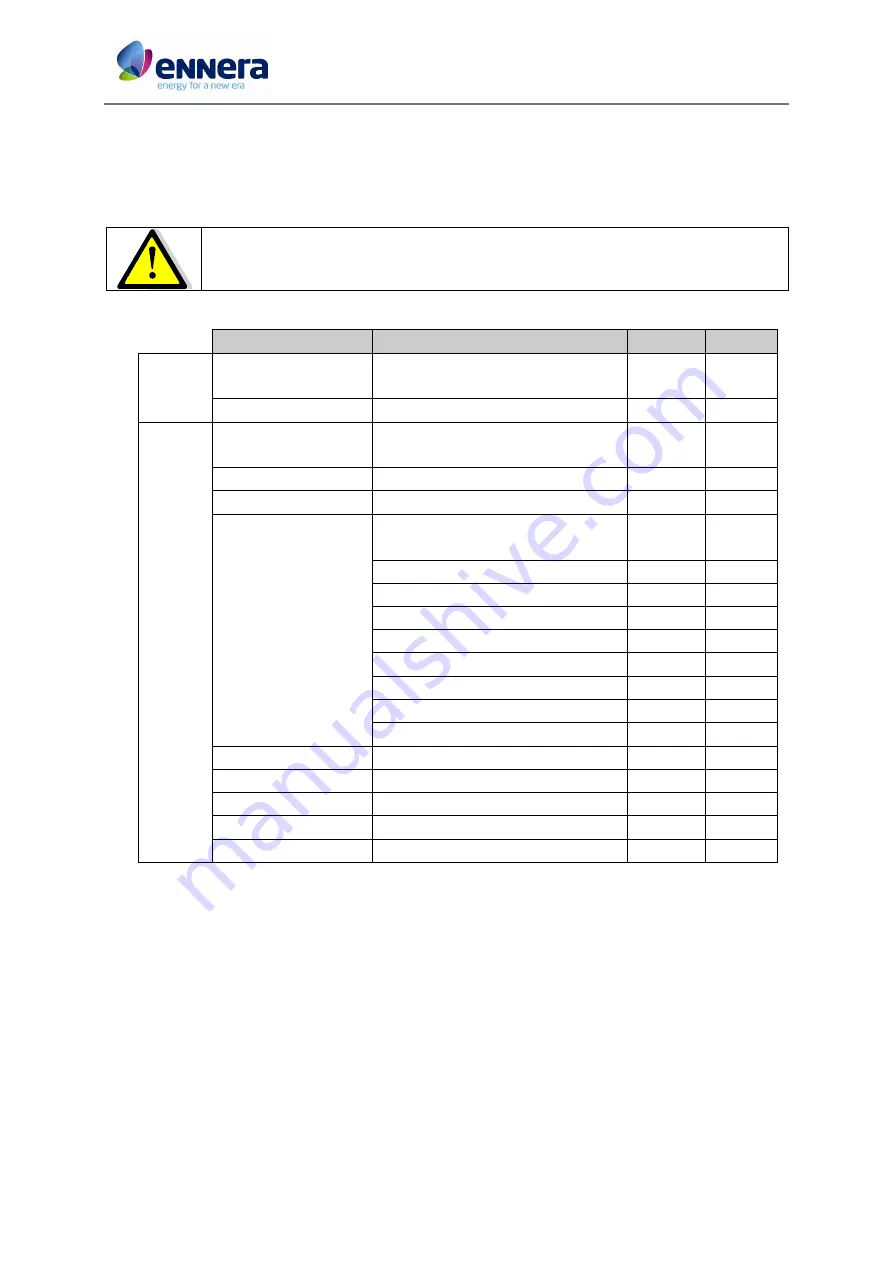

8.3.

Maintenance plan

Although the Windera S has been designed for a service lifetime of 20 years, Ennera Energy and

Mobility recommends Windera S wind turbine be checked on an annual basis to make the

maintenance procedure.

CAUTION – PRIOR TO PERFORMING ROUTINE MAINTENANCE, FOLLOW PROCEDURE

FOR THE PROPER SHUTDOWN OF THE WIND TURBINE

This preventive maintenance procedure consists of:

TASK

DESCRIPTION

QUARTERLY ANNUALLY

From base

Check for smooth running

Listen for any abnormal noises or excessive

vibrations

X

X

Check tower base bolts

M30 bolts

X

X

Lower

wind

turbine

Blade's visual inspection

Especially at the blade root and leading

edge. Absence of cracks

-

X

Clean slip rings

Remove carbon dust

-

X

Check slip rings brushes

Check brushes wear

-

X

Check tightening torque of

bolts

With torque wrench (see section 6.3 for

corresponding torque)

-

X

Tower base bolts [M30]

-

X

Tower flange bolts [M12]

-

X

Tower-yaw bolts [M10]

-

X

Yaw-generator bolts [M10]

-

X

Hub bolt [M16]

-

X

Blade bolts [M10]

-

X

Tail bolts [M8]

-

X

Brake bolts [M6]

-

X

Corrosion

Verify painting status and corrosion

-

X

Check cables connection

Verify connections

-

X

Check covers

Fixing of covers: Yaw cover, front cover

X

Verify converter inside

No water inside converter

-

X

The bearings used are self lubricated so no lubrication process is needed.

In the Annex 4 and 5, the Preventive and Corrective Maintenance Control Forms are attached.