4

017-950-B1-001, Rev. A (07/2020)

1. After wiring battery cable kit, battery sense cables and PTS

[8]

, as shown in Section 2,

verify DC/Battery breaker

[6]

is OFF.

2. Connect the Smart AlphaGuard™ (SAG) wire harness to SAG port

[11]

.

3. Connect the Tamper Switch and RF cable to the transponder

[13 and 14]

.

4. Verify the SPI’s (Service Power Inserter)

ON / ALT

Toggle Switch is in the

ALT

position.

5. Connect the SPI’s input cable to the Output 1 Connector

[1]

. If a 2nd

SPI / ALT Box is present connect input cable to Output 2 Connector

[2]

.

6. Plug the optional Local/Remote Indicator (LRI) cable into the LRI connector

[7]

. For

existing LRI installations, use LRI adapter kit,

p/n 875-952-20

.

7. Turn AC breaker

ON

and verify it is the correct utility voltage at the outlet (per unit’s

nameplate voltage). If correct, plug in the XM3.1-HP line cord into the utility outlet.

8. Verify correct battery voltage and polarity on battery cable connector (see Fig. 2-1) with a

digital voltmeter; if correct, plug the battery cable connector into Inverter Module

[9]

.

4.0 Power Supply Connections

(Refer to Fig. 1-1)

Fig. 4-1, SPI toggle switch

(shown in ALT position)

ALT ON

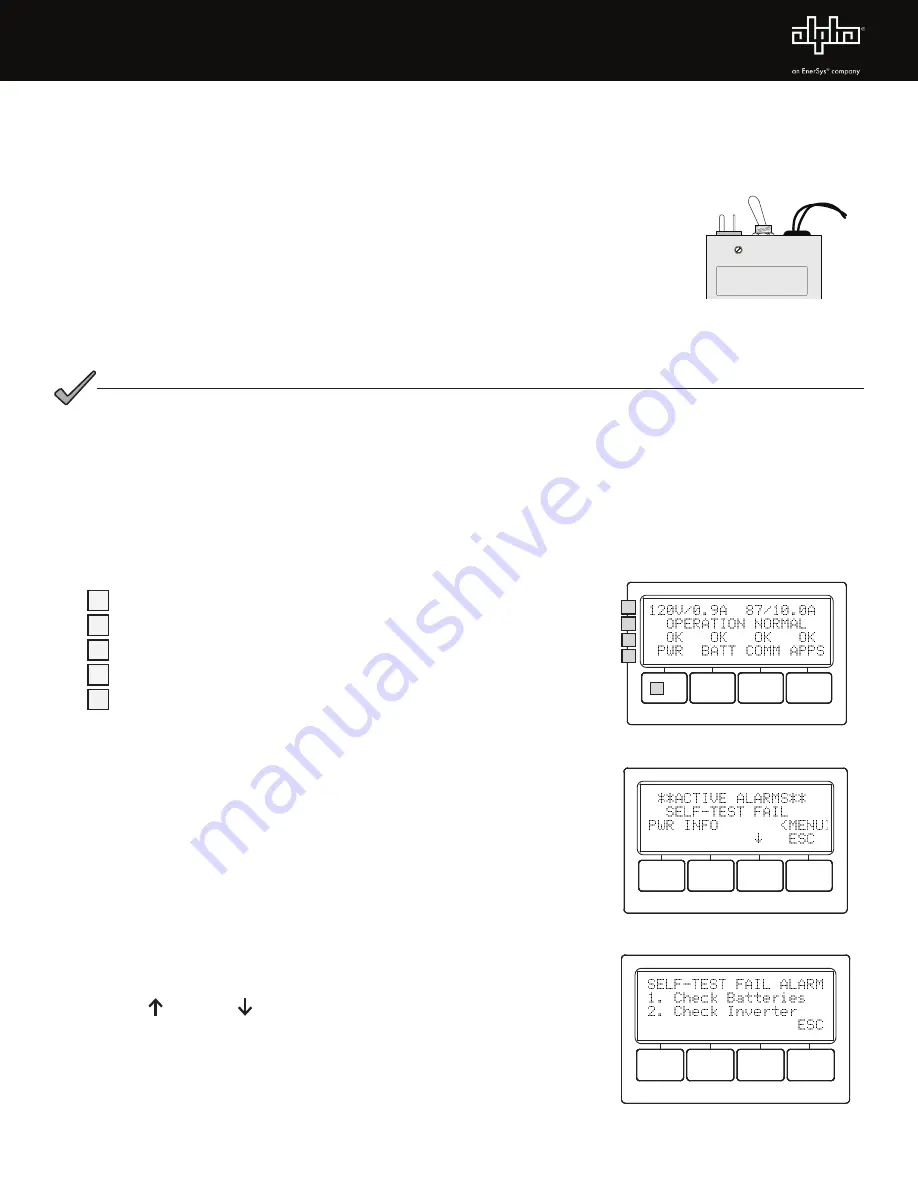

5.0 Using the Smart Display

All operational functions, system testing, menus and alarms are available via the illuminated Smart Display. Display

functions are accessible by following the indicated prompts above the four softkeys. Descriptions of the display functions

are detailed below. Press any of the softkeys to activate the Smart Display. For Smart Display functionality, an EMM

module is required to be installed in the Communications Module.

1

1st line: Displays Input and Output Voltage/Current

2

Describes Power Supply Mode of Operation

3

Describes Status of Functions

4

Functionality top level menu PWR, BATT, COMM and APPS

5

Softkeys (Menu-driven

system configuration)

Fig. 6-2, Self-Test Fail Alarm Menu,

with suggestions for corrective actions

6.0

Startup, Battery Configuration and Self-Test

6.1 Initial startup

1. After completing all the steps in Section 4.0

,

Power Supply Connections

,

turn the DC/Battery breaker

[6]

ON. The Smart Display will cycle through

its functions (approximately 60 seconds) verifying proper operation.

During this time, the XM3.1-HP may perform an automatic 5 second

Self-Test to verify whether a battery string is connected to the power

supply system by checking the battery string voltage. Upon successful

completion, the Smart Display will indicate

“OPERATION NORMAL”.

From this screen, proceed to Section 6.2,

Battery Configuration.

2. If power supply alarms are present and do not clear after 60 seconds,

press the softkey associated with the alarm to see the ACTIVE ALARM

list.

3. Press

UP

or

DOWN

to select the active alarm.

4. Press

ENTR

to select the alarm and display diagnostic information.

Press

ESC

to return to the alarm list. Refer to the XM3.1-HP Power

Supply Technical Manual for a complete listing of alarm conditions and

recommended diagnostic solutions.

5.

Once the alarm has been cleared, the batteries can be configured in the

system as outlined in the next section.

1

4

3

5

Fig. 5-1, Smart Display with

Sample Screen

2

Fig. 6-1, Smart Display indicating a

Self-Test Fail Alarm

The power supply will boot regardless of the battery breaker position once the batteries are

connected. The inverter will not run, but the LCD screen will turn on and display instructions for

applying AC power or closing the breaker.

NOTICE: