Appendix

EngyVolt RV12

36

connection to SCADA or other communications systems using the Modbus Protocol RTU

slave protocol. The Modbus Protocol establishes the format for the master's query by

placing into it the device address, a function code defining the requested action, any data

to be sent, and an error checking field. The slave's response message is also constructed

using Modbus Protocol. It contains fields confirming the action taken, any data to be

returned, and an error-checking field. If an error occurs in receipt of the message, the

device will make no response. If the device is unable to perform the requested action, it will

construct an error message and send it as the response.

The electrical interface is 2-wire RS485, via 3 screw terminals. Connection should be made

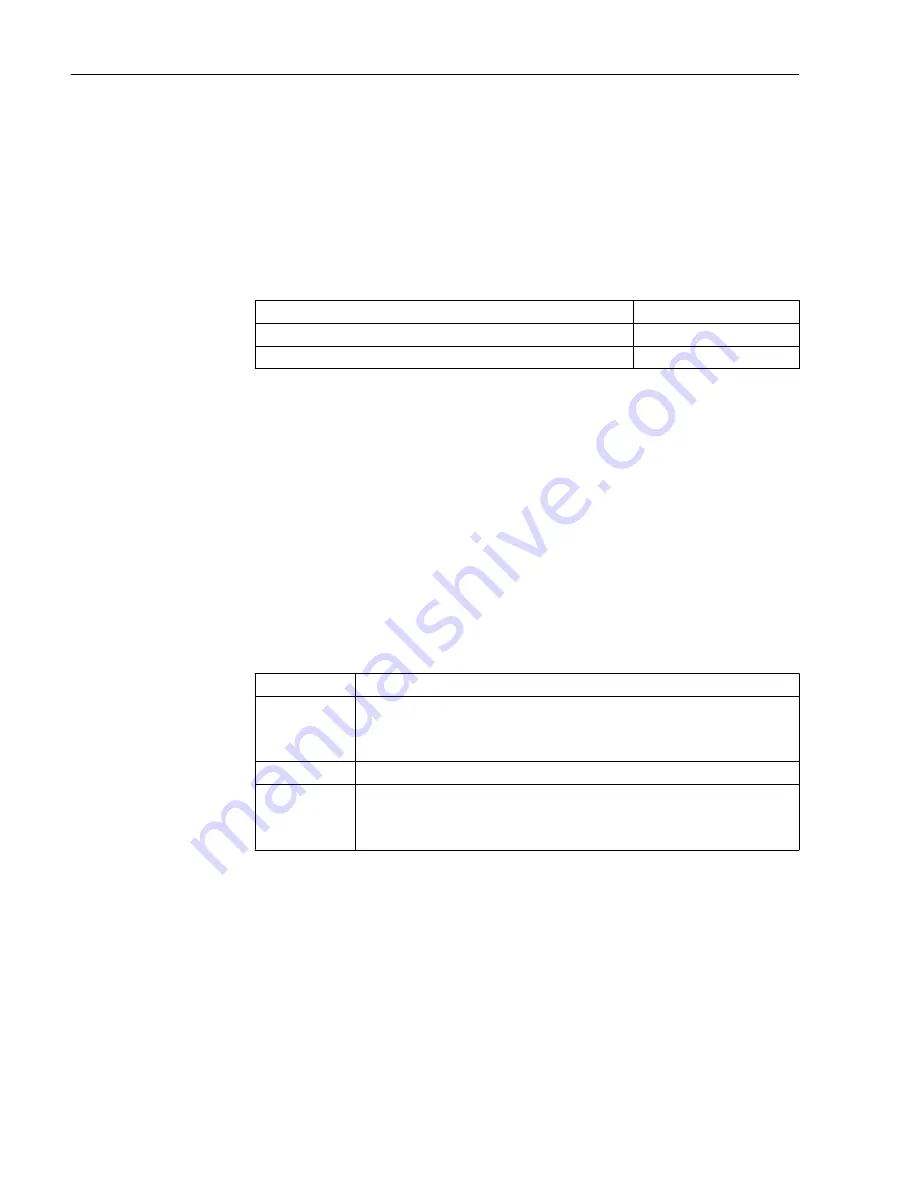

using twisted pair screened cable and the following electrical data:

Nominal inductivity

0.2 µH/ft

Nominal capacity line-line

24 pF/ft

Maximum operating voltage

300 V RMS

All "A" and "B" connections are daisy chained together. The screens should also be

connected to the “Gnd” terminal. To avoid the possibility of loop currents, an Earth

connection should be made at only one point on the network. Line topology may or may

not require terminating loads depending on the type and length of cable used. Loop (ring)

topology does not require any termination load. The impedance of the termination load

should match the impedance of the cable and be at both ends of the line. The cable should

be terminated at each end with a 120 Ω resistor. The load capacity of the resistor should

be 0.25 W. A total maximum length of 1

200 m (3

900 ft) is allowed for the RS485

network. A maximum of 32 electrical nodes can be connected, including the controller.

The address of each EngyVolt device can be set to any value between 1 and 247. Broadcast

mode (address 0) is not supported. The maximum latency time of an EngyVolt device is

60 ms, i.e. this is the amount of time that can pass before the first response character is

output. The supervisory program must allow this period of time to elapse before assuming

that the device is not going to respond.

The format for each byte in RTU mode is:

Coding system

8-bit per byte

Data format

4 bytes (2 registers) per parameter.

Floating point format (to IEEE 754)

Most significant register first (Default).

The default may be changed if required - See Holding Register "Register Order" .

Error check field

2 byte Cyclical Redundancy Check (CRC)

Framing

1 start bit

8 data bits, least significant bit sent first

1 bit for even/odd parity (or no parity)

1 stop bit if parity is used; 1 or 2 bits if no parity

Data coding

All data values in the EngyVolt device are transferred as 32 bit IEEE 754 floating point

numbers, (input and output) therefore each device value is transferred using two Modbus

protocol registers. All register read requests and data write requests must specify an even

number of registers. Attempts to read/write an odd number of registers prompt the device

to return a Modbus protocol exception message.

The multifunctional electrical energy meters can transfer a maximum of 40 values in a

single transaction, therefore the maximum number of registers requestable is 80.

Exceeding this limit prompts the device to generate an exception response.

Data transmission speed is selectable between 2400, 4800, 9600, 19200 and 38400

baud.

Содержание EngyVolt RV12

Страница 2: ......

Страница 27: ...EngyVolt RV12 Accessories 27 9 Accessories No accessories are available for this device...

Страница 61: ......

Страница 62: ......

Страница 63: ......

Страница 64: ...www addresses endress com...