34. Plumbing the Pool and Water

Quality System

Plumb the front panel suction and return lines as described

in Tech Bulletin #16. All of the plumbing fittings and the glue

and cleaner to accomplish this work are packed in a cardboard

box labeled Plumbing Fittings which can be found in the

pool crate. We have supplied short lengths of flex PVC to be

used here. We have also supplied lengths of 1-1/2" PVC

Schedule 40 rigid pipe for plumbing between the front of

the pool and the remotely located Water Quality System

(pump/filter/heater). If more rigid pipe is required for your

particular installation configuration, it is readily available at a

building supply store. A hardware store will probably

have shorter lengths. A good hardware store will probably also

have replacement PVC fittings but we have supplied extras and

more are generally not needed. If you do use PVC fittings from

others be sure to use deep socket “pressure” fittings and not

drain fittings.

Customers typically locate the Water Quality System so as to

simplify installation and make regular service convenient. See

Figure 34.1. Suitable drainage should be a consideration for

both this system and for the pool itself. There is always the risk

that a valve will be left inadvertently closed (when changing a

filter for example) and the 24-hour timer will turn on the circu-

lating pump and a fitting joint will fail, emptying the pool. It is

best to consider these and other scenarios during installation so

that proper planning can eliminate the chance that damage will

occur if the system leaks. Drains or sumps in the general area are

a start. It is critical to test these with a garden hose to ensure that

they work and that the floor is sloped towards them. Sometimes

it is necessary to channel the water by mounting a low dam to

the floor. Sometimes a sump pump must be installed even

though it may never be used. Every site is different but a candid

discussion with the homeowner about the possibility of future

leaks and where the water will go during the time it takes to fix

the leak is important.

The pump and filter are pre-plumbed and fasten securely to the

plastic base with 3/8" bolts and self-drilling fasteners. The com-

ponents can be assembled to suit your specific site but they are

generally installed as shown in the drawing in Tech Bulletin

#16. The heater can be located anywhere downstream of the fil-

ter. When the standard 5.5 KW electric heater is used it may be

installed directly onto the same PVC base. When installing the

electric heater be sure to leave enough clearance so that the

black locking ring on the filter has room to rotate. See Figure

34.2. Natural Gas or Propane Gas Heaters will not fit on this

base and are located so as to ensure safe distances from com-

bustible surfaces and good ventilation.

We can’t stress enough the importance of safety when installing

a gas heater. This is especially true when the heater is installed

indoors. Refer to the Raypak heater manual reprinted in its

entirety as Tech Bulletin #12 for specific safety requirements

and recommendations. Remember, the gas and propane heaters

must be installed by a licensed professional.

The drawing in Tech Bulletin #16 shows how we recommend

plumbing the pump/filter/heater. The layout allows each compo-

nent to be removed from the system by unscrewing a union

rather than cutting pipe. A tee with hose bib is included

for draining water prior to changing the filter or simply for

partially draining the pool. See Figure 34.3.

PVC Glue should be used on all non-threaded fittings. Clean all

non-threaded fittings with the PVC cleaner supplied before

applying the glue to both surfaces. Push the fittings firmly

together, turn 1/8 turn, and hold for 30 seconds. Connecting

PVC plumbing is very straightforward. A watertight seal at

every joint takes practice, however. Should a joint leak, cut out

the part and try again with fresh pipe and fittings.

Teflon sealant should be used on all plastic threaded fittings but

not on the threaded ring that connects 2 halves of a union.

Follow directions on the sealant container provided. Do not

Fig 34.1: Typical plumbing and water quality system placement.

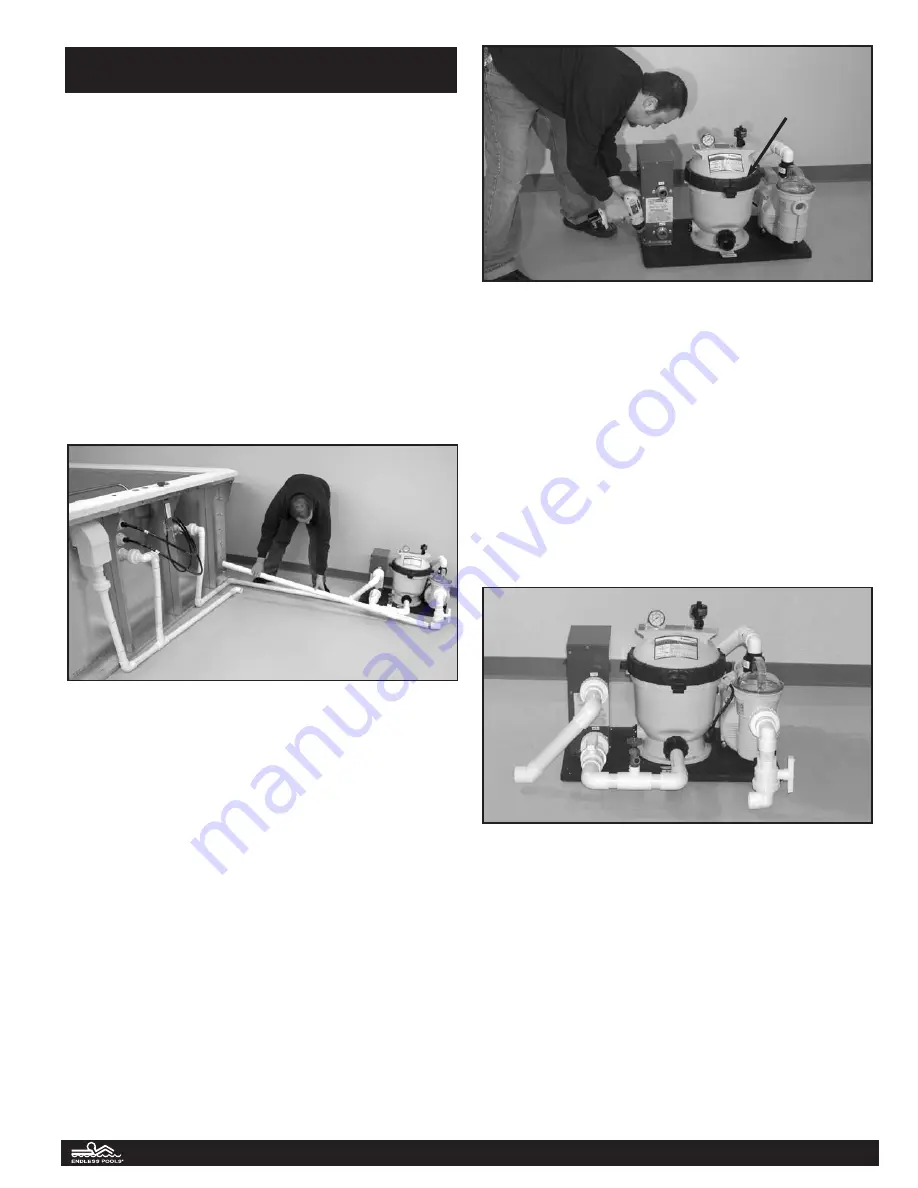

Fig 34.2:The pump, filter and standard electric heater all fasten to the PVC base.

Fig 34.3:Typical water quality system with electric heater.

21

Locking Ring