12433-10-0109

Page 12

On the main burner, the burning gas forms a primary flame and a

secondary flame. The primary flame is blue and about 3/16" (5mm)

high. The secondary flame is very pale blue, 3 inches (76mm) to 5

inches (127mm) high. Dust in the combustion air will produce an

orange flame. Do not mistake it for an improper yellow flame.

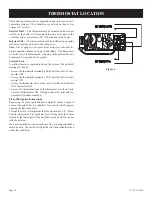

Figure 8

Steps in Removing Main Burner, Orifice and Valve

1. Disconnect the thermopile and pilot supply line at the pilot

burner.

2. Remove the burner compartment cover 5/16" (8mm) socket

suggested.

3. Remove screw holding left side of burner and lift out.

4. Main burner orifice is now accessible. Use 1/2" (13mm) box end

wrench to remove and apply non-hardening pipe dope sparingly

to orifice threads when replaced.

5. To remove the entire gas valve the nut holding the orifice fitting

to the chamber must be removed and the gas supply to the valve

disconnected. After this, the valve and orifice elbow can be

removed as a unit.

Cleaning The Pilot Burner

Cleaning of the pilot may be an annual necessity due to spiders.

After removing the supply tubing and orifice, use a pipe cleaner

or wire to clean the entire internal part of the pilot.

Cleaning the Combustion Chamber and Main Burner

When the main burner and vent cap are removed, all internal areas of

the combustion chamber are accessible for cleaning with a vacuum

hose. The main burner may be cleaned by forcing water into the

ports and the throat of the burner. The burner should be blown dry

or heated to dry all water out before reinstalling.

The pilot flame is blue and goes toward the main burner and

thermopile horizontally. A slight yellow tip on the flame is normal.

The pilot flame must surround and extend approximately 1/4"

(6mm) beyond the thermopile, and must extend beyond the first

row toward the second row of main burner ports.

Figure 7

Pilot FlaMe cHaracteristics

Main Burner FlaMe cHaracteristics

Maintenance

M AIN BURNER

PILO T

FLAM E

BURNER

CHANNEL

THERM O PILE

Содержание DV-210-SG

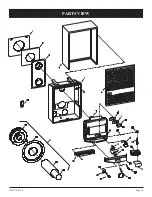

Страница 15: ...12433 10 0109 Page 15 PARTS VIEW...