2

KEYSTONE

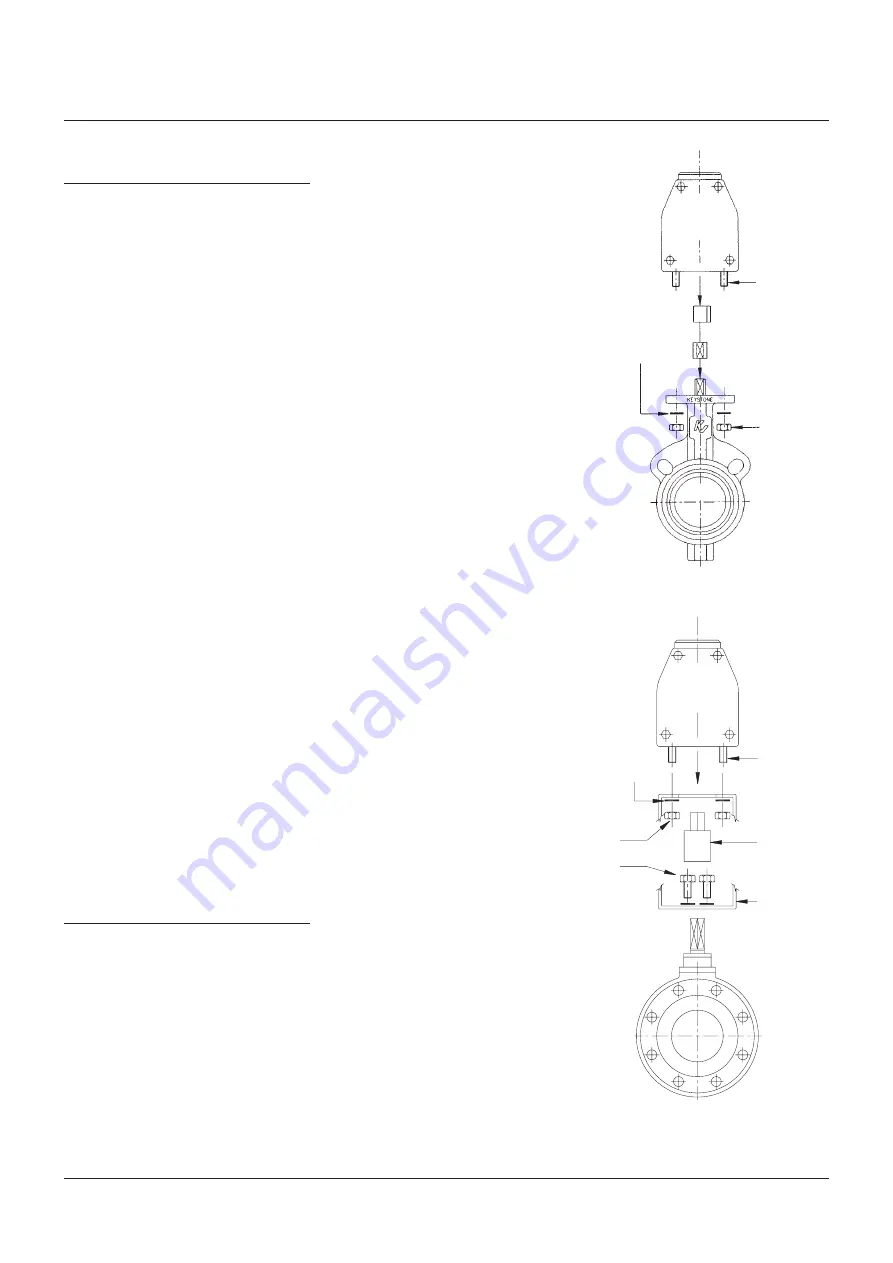

FIGURE 79 PNEUMATIC ACTUATOR

OPERATING AND MAINTENANCE INSTRUCTIONS

STANDARD INSTALLATION - DOUBLE &

SINGLE ACTING UNITS

These instructions assume that the actuators

are installed with the cylinder axis parallel to

the axis of the valve bore (In Line).

Single acting actuators are supplied as

FAIL-CLOSE units as standard.

Reverse acting FAIL-OPEN must be specified at

the time of order.

The actuator is mounted as follows:

1. Ensure that the valve and actuator are both

in the following positions:

Double Acting units - fully closed

Single Acting units - air fail mode

(normally closed)

2. Check that the actuator mounting studs are

tightly secured in the actuator housing.

3. Install the correct adaptor, if required, into

the actuator (fig. 1 - direct mounting) or

install the correct coupling and bracketry,

if required, to the valve (fig. 2 - bracket

mounted option).

See Notes 1 & 2

4. Mount the actuator onto the valve flange or

the bracket and secure using a lockwasher

and nut on each mounting stud.

5. Before installing the valve/actuator

assembly in a piping system, the disc travel

should be verified.

6. When installing the valve/actuator assembly

into pipeline, ensure that the specific

instructions relating to the valve installation

are followed. For valves which need to be

fitted with the valve in a position other than

fully closed, it may be necessary to fit the

valve into the pipeline prior to mounting the

actuator to the valve. Rubber lined butterfly

valves are an example of this.

7. For valves which need to be installed in the

pipeline prior to fitting the actuator, ensure

that the valve is operated into its failsafe

position before mounting the actuator onto

the valve.

NON STANDARD INSTALLATION - DOUBLE &

SINGLE ACTING UNITS

In circumstances where the actuator is

required to be installed in the transverse

position i.e. at right angles to the valve bore

(Across Line), the actuator must be rotated

through 90°.

This is achieved in the following manner:

1. Remove the actuator from the valve or the

bracket by unscrewing the 4 fixing nuts and

withdraw it vertically from the valve.

2.

79U/E Models

- remove the double ‘D’

adaptor located in the bore at the bottom of

the actuator and re-fit, locating in previously

unused keyway of shaft.

NOTES

1. The adaptor should be lightly tapped or pressed

into the actuator.

2. The coupling should be lightly tapped or pressed

onto the valve stem.

Excessive force should not be used (the use of a

lubricant such as Coppaslip is recommended).

FIGURE 1

FIGURE 2

Pneumatic

actuator

Pneumatic

actuator

Ball

valve

Stud

Nut

Stud

Nut

Bolt

Valve

Adaptor

if required

Adaptor

if required

Coupling

if required

Bracket

if required

Lockwasher

Lockwasher

3. Refit actuator to the top of the valve. (note:-

on models 036/065/090 adaptors may not be

required to be fitted ie directly mounted, in

this case simply use the previously unused

keyway.)