Instruction Manual

D200149X012

3610J and 3620J Positioners

September 2017

35

D

Do not remove the actuator from the valve while the valve is still pressurized.

D

Disconnect any operating lines providing air pressure, or a control signal to the actuator. Be sure the actuator cannot

suddenly open or close the valve.

D

When disconnecting any of the pneumatic connections, natural gas, if used as the supply medium, will seep from the

unit and any connected equipment into the surrounding atmosphere. Personal injury or property damage may result

from fire or explosion if appropriate preventative measures are not taken, such as adequate ventilation and the

removal of any ignition sources.

D

Use bypass valves or completely shut off the process to isolate the valve from process pressure.

D

Vent the actuator loading pressure and disconnect positioner supply pressure.

D

For explosion proof applications, disconnect power before removing the converter housing cap in an explosive

atmosphere.

D

Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D

Check with your process of safety engineer for any additional measures that must be taken to protect against process

media.

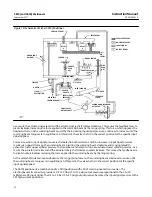

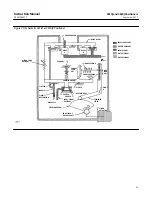

Figure 22. Schematic of Fisher 3620J Positioner

38A6593‐A

B2150

MINOR LOOP

GAIN ADJ

ZERO ADJ

RANGE SPRING

COARSE

SPAN

ADJ

CROSS‐OVER ADJ

RELAY BEAM

RELAY

B

RELAY

A

SUPPLY PRESSURE

NOZZLE PRESSURE

INPUT SIGNAL

OUTPUT SIGNAL

AIR

SUPPLY

FINE

SPAN

ADJ

PIVOT

B

FEEDBACK

LEVER

INPUT MODULE

PIVOT A

FLAPPER

NOZZLE

FIXED

RESTRICTION

CAVITY A

CAVITY B

POSITIONER CAM

END VIEW OF

ROTARY SHAFT

SPRING AND DIAPHRAGM

ACTUATOR

SUMMING BEAM

COUNTER SPRING

FLAPPER

NOZZLE

FIXED

RESTRICTION

MAGNET

COIL 4 TO

20 mA INPUT

SUPPLY