30

AGL_HP_ST_ZHK1P_EN_Rev00

6.4 Replacing a compressor

CAUTION

Inadequate lubrication! Bearing destruction!

For systems with a

ref rigerant accumulator, exchange the accumulator af ter replacing a

compressor with a burned-out motor. The accumulator oil ret urn orif ice or

screen may be plugged with debris or may become plugged. This will res ult

in starvation of oil to the new compressor and a second failure.

Remove ref rigerant and oil completely from the replaced compressor.

6.4.1 Compressor replacement

In the case of a motor burnout, the majority of contaminated oil will be removed with the

compressor. The rest of the oil is cleaned through the use of suction and liquid line filter dr y ers. A

100 % activated alumina suction line f ilter dryer is recommended but must be removed af ter

72 hours. When a single compressor or tandem is exchanged in the field, it is possible that a major

portion of the oil may still be in the system. While this may not af f ect the reliability of the

replacement compressor, the extra oil will add to rotor drag and increase power usage.

6.4.2 Start-up of a new or replacement compressor

Rapid charging only on the suction side of a scroll-equipped system can occas ionally res ult in a

temporary no-start condition for the compressor. The reason for this is t hat, if t he f lanks of t he

scrolls happen to be in a sealed position, rapid pressurisation of the low s ide wit hout opposing

high-side pressure can cause the scrolls to seal axially. As a result, until the pressures event ually

equalise, the scrolls can be held tightly together preventing rotation. The b est way t o avoid t his

situation is to charge on both the high and low sides simultaneously at a rate which does not result

in axial loading of the scrolls.

A minimum suction pressure specified in the published operating envelope must be maintained

during charging. Allowing the suction pressure to drop below that value may overheat t he s crolls

and cause early drive bearing and moving parts damage. Never install a syst em in t he f ield and

leave it unattended when it has no charge, a holding charge, or wit h t he s ervic e v alves c losed

without securely electrically locking out the system. This will prevent unauthorised personnel f rom

accidentally operating the system and potentially ruining the compressor b y o perating wit h no

ref rigerant.

Do not start the compressor while the system is in a deep vacuum.

Internal arcing

may occur when a scroll compressor is started in a vacuum causing burnout of t he int ernal lead

connections.

6.5 Lubrication and oil removal

CAUTION

Chemical reaction! Compressor destruction!

Do not mix up ester oils with

mineral oil and/or alkyl benzene when used with chlorine-f ree (HFC)

ref rigerants.

The compressor is supplied with an initial oil charge. The standard oil charge f or use with

ref rigerant R410A is a polyolester (POE) lubricant Emkarate RL 32 3MAF. In the field the oil lev el

could be topped up with Mobil EAL Arctic 22 CC if 3MAF is no t av ailable. S ee nameplat e f or

original oil charge shown in litres. A field recharge is from 0.05 to 0.1 litre less.

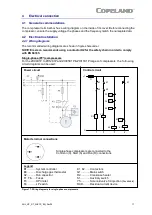

One disadvantage of POE is that it is far more hygroscopic than mineral oil

– see

Figure 25

. Only

brief exposure to ambient air is needed f or POE to absorb suf f icient moisture to make it

unacceptable f or use in a ref rigeration system. Since POE holds moisture more readily than

mineral oil it is more difficult to remove it through the use of vacuum. Co mpress ors s upplied b y

Emerson contain oil with low moisture content, and it may ris e during t he s yst em as sembling

process. Theref ore it is recommended that a properly sized f ilter dryer is installed in all POE

systems. This will maintain the moisture level in the oil to less than 50 ppm. If oil is charged int o a

system, it is recommended to use POE with a moisture content no higher than 50 ppm.

If the moisture content of the oil in a ref rigeration system reaches unacceptabl y high levels,

corrosion and copper plating may occur. The system should be evacuated d own t o 0.3 mbar o r

lower. If there is uncertainty as to the moisture content in the syst em, an o il s ample s hould b e

taken and tested for moisture. Sight glass/moisture indicators currently available can be used wit h

the HFC ref rigerants and lubricants; however, the moisture indicator will just s how t he moist ure

content of the refrigerant. The actual moisture level of POE would be higher than t he s ight g las s

indicates. This is due to the high hygroscopicity of the POE oil. To determine the ac tual moisture

content of the lubricant, samples have to be taken from the system and analysed.

Содержание COPELAND ZH04K1P

Страница 10: ...AGL_HP_ST_ZHK1P_EN_Rev00 7 ZHI46K1P ...