10

AGL_HP_ST_ZHK1P_EN_Rev00

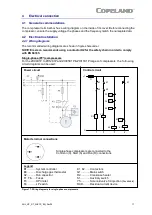

Ref er to

Figure 5

above and procedure below for the brazing of the suction and discharge lines t o

a scroll compressor.

▪

The copper-coated steel tubes on scroll compressors can be brazed in approximately the same

manner as any copper tube.

▪

Recommended brazing materials: any silf os material is recommended, pref erably with a

minimum of 5 % silver. However, 0 % silver is acceptable.

▪

Be sure tube f itting inner diameter and tube outer diameter are clean prior to assembly.

▪

Using a double-tipped torch, apply heat in area 1.

▪

As the tube approaches brazing temperature, move the torch flame to area 2.

▪

Heat area 2 until braze temperature is attained, moving the torch up and down and rot ating

around the tube as necessary to heat the tube evenly. Add braze mat erial to t he joint while

moving the torch around the joint to flow braze material around the circumference.

▪

Af ter the braze material flows around the joint, move the torch to heat area 3. This will d raw t he

braze material down into the joint. The time spent heating area 3 should be minimal.

▪

As with any brazed joint, overheating may be detrimental to the final result.

To disconnect:

▪

Heat joint areas 2 and 3 slowly and uniformly until the braze material softens and the t ube c an

be pulled out of the fitting.

To reconnect:

▪

Recommended brazing materials: Silfos with minimum 5 % silver or silver braze used on o ther

compressors. Due to the different thermal properties of steel and copper, brazing proc edures

may have to be changed from those commonly used.

NOTE: Since the discharge stub contains a check valve, care must be taken not to overheat

it to prevent brazing material from flowing into it.

NOTE: Since the injection tubing design of the ZHI*K1P compressors includes some

O-rings, a wet rag or any other suitable heat protection device must be used when brazing

the injection line to the compressor.

3.4 Pressure safety controls

3.4.1 High-pressure protection

Applicable regulations and standards, for example EN 378-2, shall be followed to apply appropriate

control and ensure that the pressure never exceeds the maximum limit.

High-pressure protection is required to stop the compressor operating outside the allowable

pressure limits. The high-pressure control must be installed correctly, which means that no servic e

valve is allowed between the compressor and the pressure protection.

The high-pressure cut-out setting shall be determined according to the applic able s tandard, t he

type of system, the refrigerant and the maximum allowable pressure PS.

3.4.2 Low-pressure protection

CAUTION

Operation outside the application envelope! Compressor breakdown!

A

low-pressure protection shall be f itted in the suction line to stop the

compressor when it operates outside the envelope limits.

Applicable regulations and standards shall be followed to apply appropriate control and ens ure that

the pressure is always above the required minimum limit.

Low-pressure protection is required to stop the compressor operating outside the allowable

envelope limits. The low-pressure control must be installed correctly into the suc tion line, whic h

means that no service valve is allowed between the compressor and the pressure protection.

The minimum cut-out setting shall be determined according to t he ref rigerant and t he allowed

operation envelope

– see Select software at

Содержание COPELAND ZH04K1P

Страница 10: ...AGL_HP_ST_ZHK1P_EN_Rev00 7 ZHI46K1P ...