AGL_HP_ST_ZHK1P_EN_Rev00

27

situation and consequent damage to the compressor. The hysteresis of the low-pres sure c ontrol

dif ferential has to be reviewed since a relatively large volume of gas will re-expand f rom t he hig h

side of the compressor into the low side after shutdown.

For pressure control

setting, never set the low-pressure limiter to

shut off outside of the

operating envelope.

To prevent the compressor from running into problems during such

faults as loss of charge or partial blockage, the low-pressure limiter should not be set lower

than the minimum suction pressure allowed by the operating envelope.

5.11 Pump-out cycle

A pump-out cycle has been successfully used by some manufacturers of large rooftop units. Af t er

an extended off period, a typical pump-out cycle will energize the compressor for up to one second

f ollowed by an off time of 5 to 20 seconds. This cycle is usually repeated a second time, t he t hird

time the compressor stays on for the cooling cycle.

5.12 Minimum run time

Emerson recommends a maximum of 10 starts per hour. There is no minimum of f t ime b ecause

scroll compressors start unloaded, even if the system has unbalanced pressures. The most critical

consideration is the minimum run time required to return oil to the compressor af t er s tart -up. To

establish the minimum run time, a sample compressor equipped with an external oil sight g las s is

available f rom Emerson. The minimum on time becomes the time required f or oil lost during

compressor start-up to return to the compressor sump and to restore a minimal o il lev el t hat will

ensure oil pick-up through the crankshaft. Cycling the compressor for a shorter period than this, for

instance to maintain very tight temperature control, will result in progressive loss of oil and damage

to the compressor.

5.13 Shut-off sound

Scroll compressors incorporate a device that minimizes reverse rotation. The residual momentary

reversal of the scrolls at shut-off will cause a clicking sound, but it is entirely normal and has no

ef f ect on compressor durability.

5.14 Supply frequency and voltage

There is no general release of standard Copeland scroll compressors for use with variable s peed

AC drives. There are numerous issues that must be taken into account when applying scroll

compressors with variable speed, including system design, inverter selection, and operating

envelopes at various conditions. Only frequencies from 50 Hz to 60 Hz are acceptable. Operation

outside this frequency range is possible but should not be d one without s pecif ic A pplicat ion

Engineering review. The voltage must vary proportionally to the frequency.

If the inverter can only deliver a maximum voltage of 400 V, the amps will increase when the speed

is above 50 Hz, and this may give rise to nuisance tripping if operation is near the maximum power

limit and/or compressor discharge temperature limit.

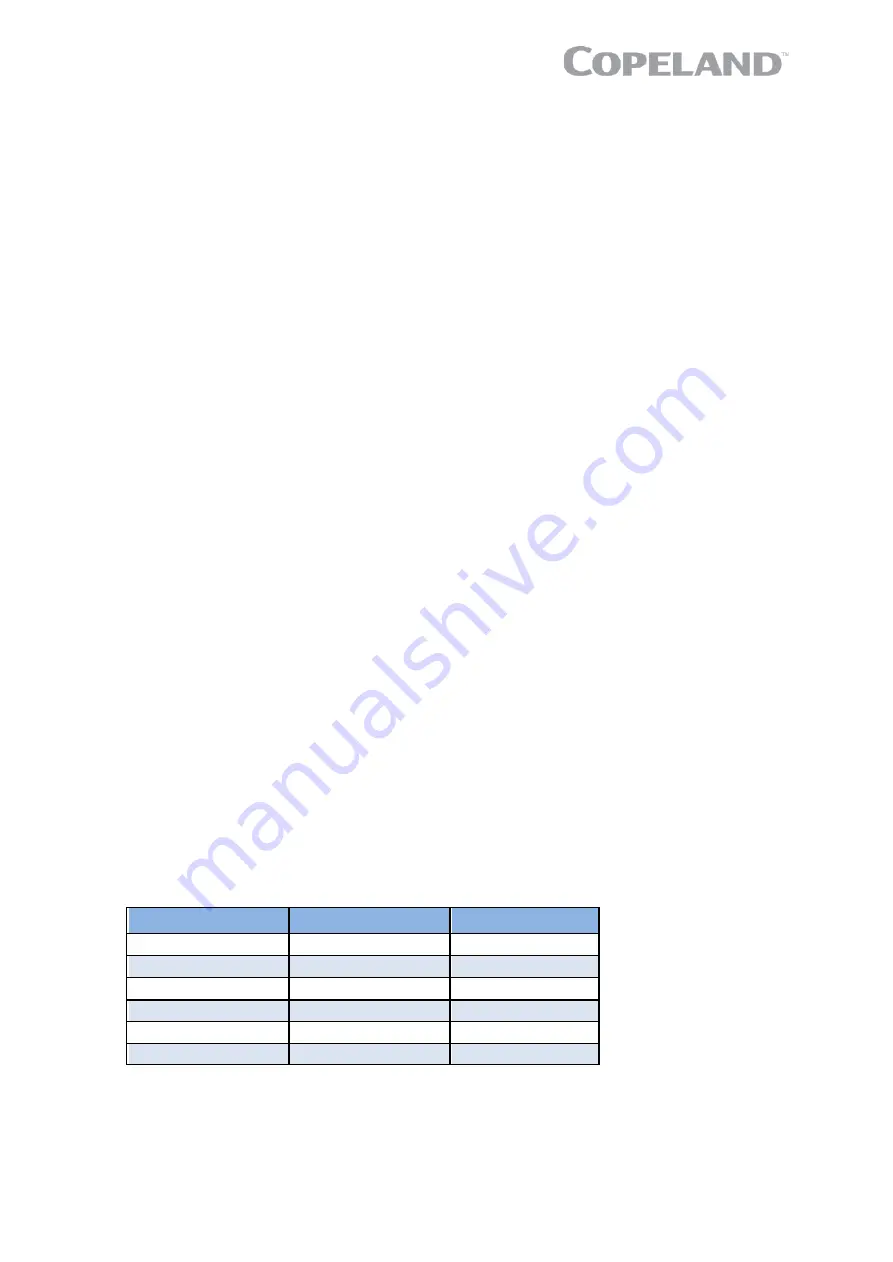

The last digit of the model motor code indicates which frequency and voltage must b e applied

–

see

section 2.2 "Nomenclature"

. The availability of codes per compressor model can be checked

in

section 2.1 "Compressor range"

.

50 Hz

60 Hz

Code

380

– 420 – 3 ph

460

– 3 ph

D

220

– 240 – 1 ph

265

– 1 ph

J

380

– 420 – 3 ph

---

M

220

– 240 – 3 ph

---

R

220

– 240 – 1 ph

---

Z

200

– 220 – 3 ph

220

– 230 – 3 ph

5

Table 6: Typical electrical codes in ZH(I)* compressors

Содержание COPELAND ZH04K1P

Страница 10: ...AGL_HP_ST_ZHK1P_EN_Rev00 7 ZHI46K1P ...