P7 INSTALLATION

5. INSTALLATION

5. 1 LOCATION

5. 2 PIPING

Incorrect suction design is one of the main causes for problems appearing during the pump installations. The

suction tube is one of the installation's main components, and it should meet the following conditions in order to

avoid future problems.

1. It should be as short and straight as possible.

2

.

The Diameter of the tube should not be smaller than the diameter of the pumps inlet.

3

.

The suction tube should be fully airtight, if not the entr y of air can cause de-priming of the pump

4

.

The suction tube should have its own means of support and should not cause tensions or strains to the pump's

flange.

5

.

Minimize the use of elbows, valves, narrowing or choking sections etc. which dangerously increase head losses

and can cause air pockets as well as entr y of air into the piping.

6

.

Each pump should have its own dedicated suction tube. If for unavoidable reasons it is necessar y to connect two

or more pumps to a single collector, the collector should have the same diameter from the first to the last outlet

and should be sufficiently sized to supply the same flow rate to all pumps.

The pump should be located nearby as close as possible the pool or spa to reduce friction loss and improve

efficiency. It is recommended at least 1.5 meter from pool water and 3 meters according to Canadian code.

1. It is suggested that

APS550P and APS 750P

with self-priming capacity for In Ground Pool application.

APS1000P and APS1500P should be installed Below Ground Level.

2. The pump should be placed on a solid foundation that will not

vibrate. It must be bolted down to reduce noise from vibration.

The area should be well drained to prevent flooding damage

the motor.

3. Install the pump in a well thermal ventilated environment and

to protect from excessive moisture.

Ensure there is enough clearance for pre-filter basket & Lid

open and motor ventilation.

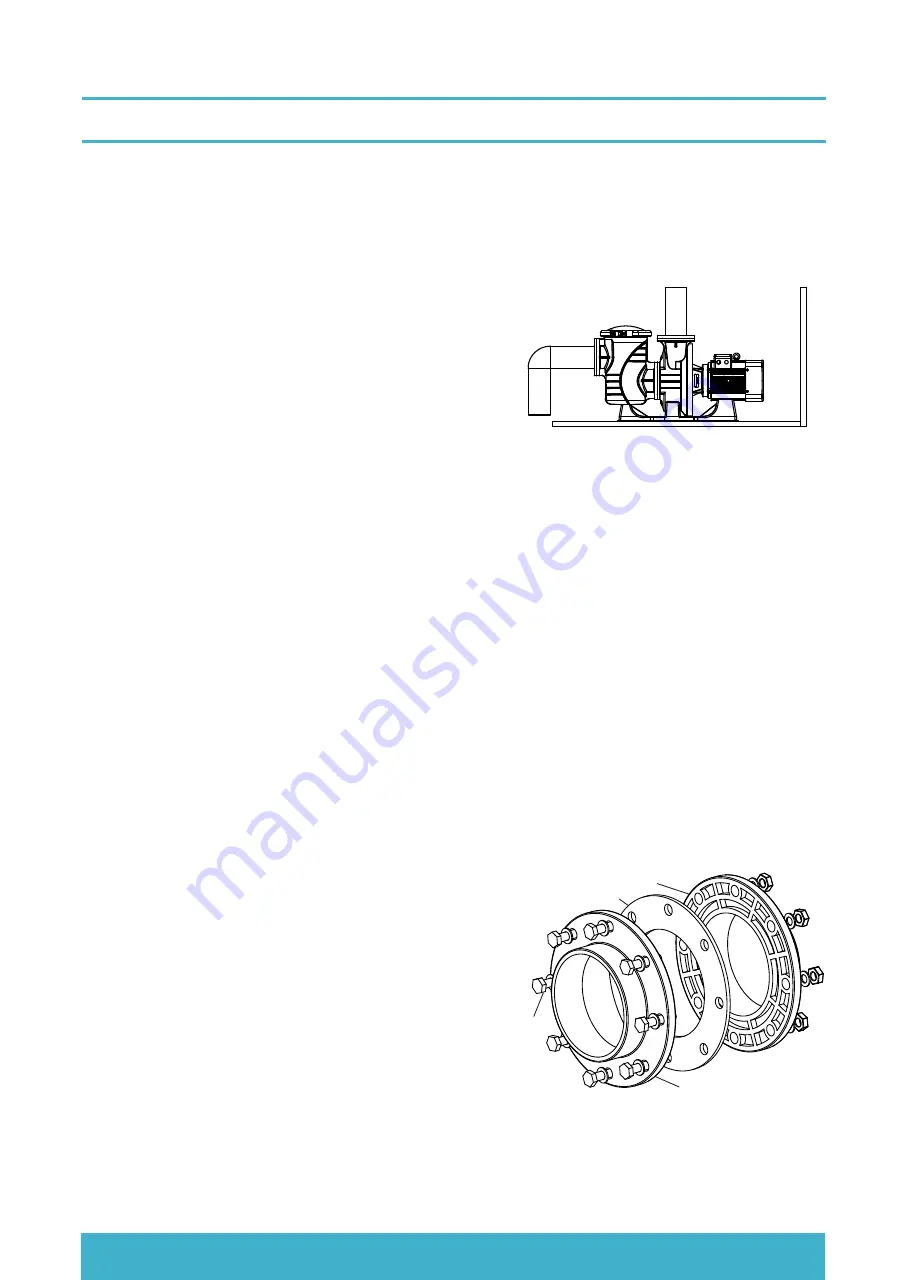

5. 3 FLANGE INSTALLATION

The Pre-Filter inlet and pump body discharge outlet are

in flange type, both ANSI (Class 150) and DIN (PN10)

standards are supported to share the same face and hole.

1. Place the 8 large bolts from the pipe flange side to the

pump.

2. Put a 3.2mm thickness gasket in between.

3. Push the bolts to the pre-filter flange hole.

4. Keep the bolt straight and lightly snug each bolt with a

wrench one by one until a squealing sound is heard to

indicate that the bolts are being excessively tightened.

Inlet or Outlet Flabge Face

Gasket

Bolt Direction

Pipe Flange