8

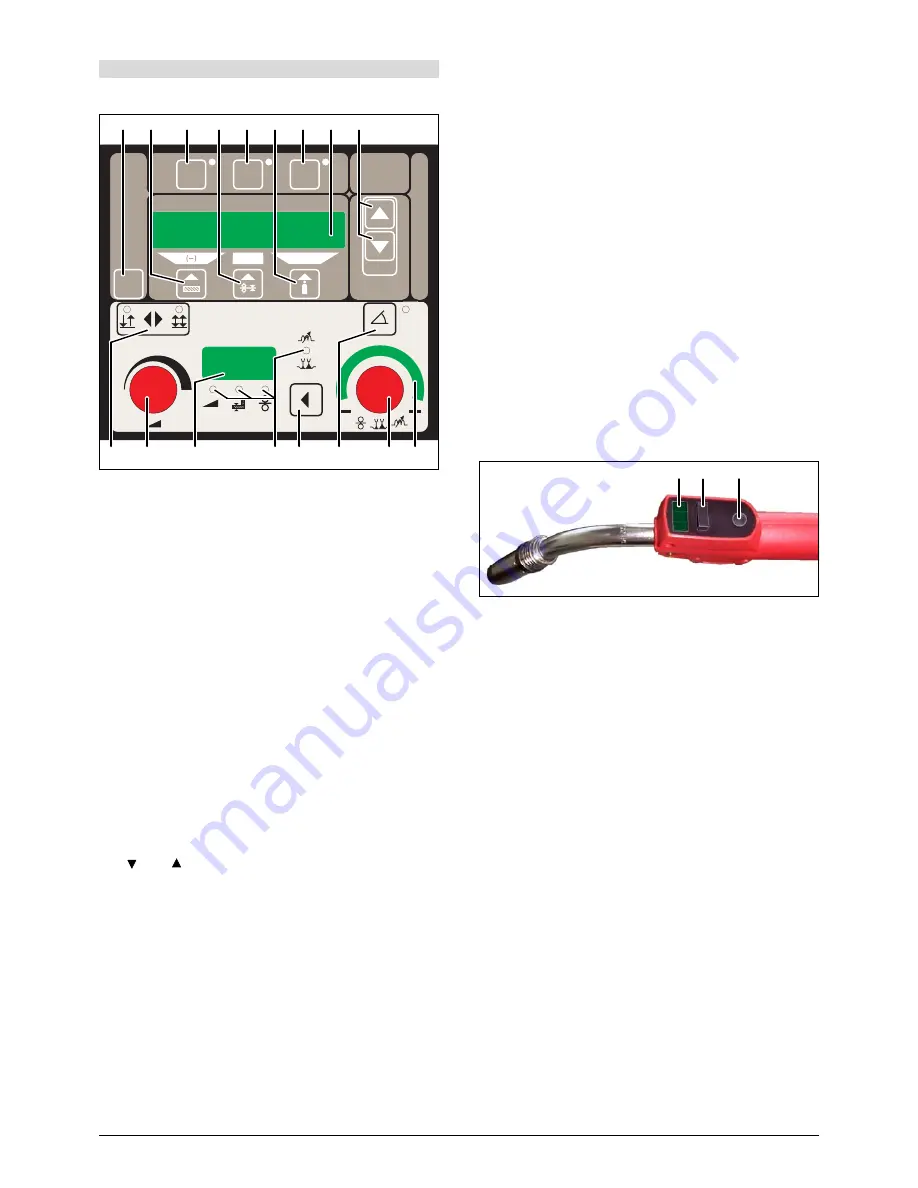

DP 20 operating panel

43

“Mode” push-button

For switching between the operation modes Normal,

Pulse, TwinPulse and Electrode.

44

“Material” push-button

For selection of the material to be welded. The push-but-

ton is also used for the “Decrementing” (-) function, e. g.,

to reduce the value of a secondary parameter.

45

“TT Save” push-button (Tiptronic)

For storage of a job.

46

“Welding wire diameter” push-button

For diameter selection of the wire to be welded. The

push-button is also used for the “End” function, with

which you can switch back to the display of the previous

menu level.

47

“TT Enter” push-button (Tiptronic)

For acknowledgement when saving a job.

48

“Gas type” push-button

For selection of the gas to be used. The push-button is

also used for the “increment” (+) function, e. g., to in-

crease the value of a secondary parameter.

49

“Tiptronic” push-button

For switching the Tiptronic mode on or off.

50

Multi-function display

For indication of all parameter values and messages.

51

and push-buttons (Enter)

For switching between the individual secondary param-

eters. Pressing both push-buttons at the same time is

used for acknowledgement (Enter).

52

“2-stroke / 4-stroke” push-button

For switching between 2-stroke and 4-stroke operation

mode. A lit LED indicates the currently selected operat-

ing mode.

53

Rotary pulse encoder for welding current / material thick-

ness

The rotary pulse encoder is used for adjustment of the

required welding current and material thickness. The ad-

justment range can be limited, depending on the select-

ed material-wire-gas combination.

54

Digital multifunction display

For indication of the primary parameters such as welding

current, material thickness (in mm), wire feed speed (in

m/min) or arc length correction.

55

“Primary parameter” LEDs

These show which primary parameter is currently indi-

cated in the multifunction display

54

.

56

“Primary parameter” push-button

For switching between welding current, material thick-

ness, wire feed speed and arc length, as indicated in the

digital multifunction display

54

.

57

“Downslope” push-button

Switches the downslope function on or off. A lit LED next

to the push-button indicates that the downslope is on.

58

“Arc length / wire speed correction” rotary pulse encoder

For correction of the arc length or wire speed (depend-

ent on setting menu extra “arc lenght control“). Up to +/-

40 % of the characteristic value can be corrected.

59

“Arc length / wire speed correction” LED indication

Indicates the degree of the correction. When the upper-

most center LED is lit, the programmed arc length/wire

speed remains unchanged; “0” is indicated in the multi-

function display

54

. Turn the rotary pulse encoder

58

left

to reduce the arc length/wire speed; turn the rotary pulse

encoder

58

right to enlarge the arc length/wire speed

.

60

Torch display

Indicates the current welding power, material thickness,

wire feed speed or arc length correction (identical with

the digital multifunction display

54

). In Tiptronic mode,

the current job set and the current job number are indi-

cated.

61

Torch rocker

For changing the welding power, material thickness or

arc length (depending on which value is being indicated

in the digital multifunction display

54

).

In Tiptronic mode, the rocker can be used to switch be-

tween the active jobs or job sets.

62

Torch “Modus” push-button

Has the same function as the “Primary parameter” push-

button

56

on the DP20 operation panel.

In Tiptronic mode this push-button can be used to switch

between job selection and job-set selection.

Current / voltage display

The actual welding voltage and welding current values are in-

dicated during the welding. After the welding procedure, the

“Hold” LED lights up and the last welding voltage and welding

current values are indicated. When the operator changes cer-

tain welding adjustments (e. g. level, program, job), the “Hold”

LED goes out and the reference values for current and volt-

age are indicated.

11 Setting into operation

TT

Save

Enter

Tiptronic

(END)

(+)

TT

Enter

Mode

mm

43 44

45 46 47 48 49 50 51

52 53

54

55 56

57

58 59

60

62

61

Содержание MULTIMIG 400puls

Страница 2: ...2 5 5 6 10 8 9 6 7 12 15 14 11 10 ...

Страница 19: ...19 Appendix mounting torch holder ...

Страница 20: ...326601 06 05 ...