MM-13- rev 01-EN

18

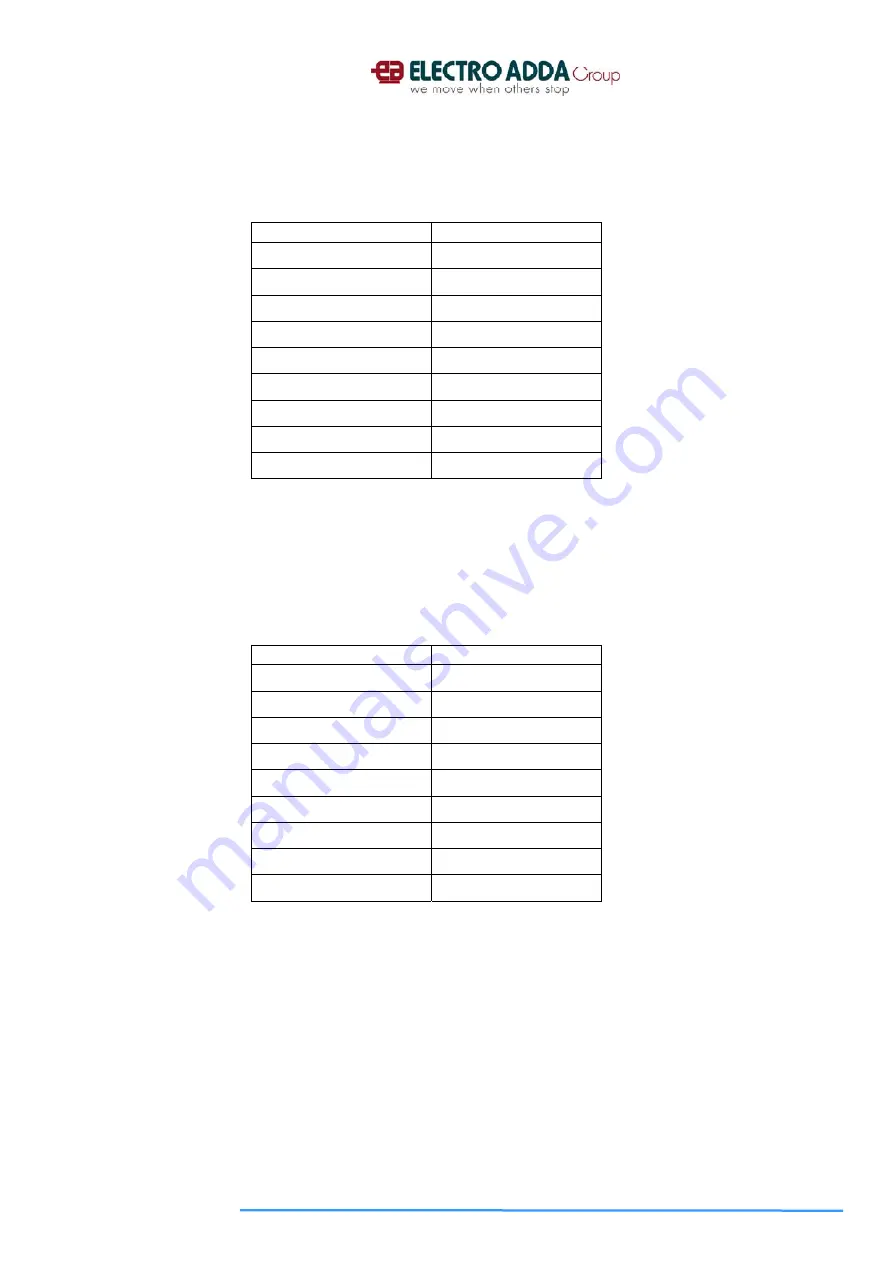

Vertical deviation

By heating the generator, the distance between the foot of the generator and the center of the shaft

(frame size) increases. This increase is mentioned in the following table:

Frame size

Increase in mm

160÷200 0.1

225÷250 0.13

280 0.15

315 0.16

355 0.18

400 0.2

450 0.23

500 0.25

560 0.28

Axial displacement

The axial displacement needs to be considered when, in case of generator with horizontal axis (as it

usually occurs), the non-drive end bearing is locked, or in case of generator with vertical axis, in

which the thrust bearing is always on the top and therefore the shaft can lengthen downwards.

The maximum elongation of the shaft is proportional to the length of the shaft and can be obtained

from the following table:

Frame size

Increase in mm

160÷200 0.4

225÷250 0.6

280 0.8

315 1

355 1.1

400 1.2

450 1.2

500 1.3

560 1.5

NOTE: Make sure that between the coupling halves (excluding rigid couplings) the axial movement is

free and continuous in order to permit expansion, in case the runner is connected directly on the

generator shaft, it is necessary to verify that the above mentioned axial displacement is possible.

Mechanical connections (G-N Line generators)

Machines with cooling airflow to and/or from the machine with air ducts are provided with connection

flanges as specified in the dimensional drawing.

Carefully clean the air ducts before connecting them to the machine and check if there are any

obstructions in the ducts. Seal the joints with appropriate gaskets and check for possible leaks in the

air ducts after they have been connected.