20

Mounting Position

Leak Test

Ignition Gas Connection

Ignition Burner Type ZT0

Mounting position

Gas pressure regulators and valves can

be mounted in vertical lines in any posi-

tion within the 360° range. In horizontal

lines they must not be mounted over-

head and only 180° in the upper sector.

The ball valve and filter can be mounted

in any desired position. Take care that

the housing does not make contact with

the wall and is clear by minimum 20

mm. Do not use the spring bolt of the

regulator and the solenoid elements of

the valves as levers.

Leak test

Check the screwed joints and flanged

connections for absence of leaks. The

leak test of the joints should be made

under pressure using only foaming

agents approved by DVGW and not

causing corrosion.

Electrical wiring of gas valves

Check that the data given on the name-

plate of the gas valves agree with the

mains voltage.

Open the terminal box of the valve.

Feed the connection cable through the

screwed union (conduit thread Pg 13.5)

and connect the terminals marked

accordingly.

L = phase

N = zero conductor

= protective conductor

(green-yellow)

Disconnectable joint

An easy-to-disconnect joint with flat

sealing (e.g. compensator) should be

provided to allow the boiler door to be

swivelled out if required for mainte-

nance work on the boiler (furnace

chamber). This compensator should

also be designed to accommodate the

axial or lateral expansion and absorb

vibrations.

Ignition gas connection

An ignition burner is used to ignite the

main gas flame. The ignition gas line is

branched out of the gas control group

between the two gas valves and instal-

led to the ignition burner on the shortest

possible way. In the case of oil and

dual-fuel burners the burner is ignited

with propane supplied through a sepa-

rate R „ propane connection. The igni-

tion gas flow rate may be adjusted on

the volumetric flow control valve of the

ignition gas valve or directly on the igni-

tion gas burner. The required gas pres-

sure for the ignition gas burner is 50-

150 mbar. It is advisable to install a gas

pressure regulator upstream of the igni-

tion gas burner. The air pressure for the

ignition gas burner should be between

10 and 30 mbar. The boiler back pres-

sure shall not be taken into account.

The air pressure should be adjusted in

accordance with the gas pressure to

ensure an undelayed ignition and a

good flame pattern.

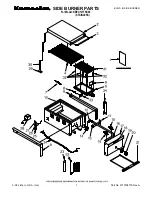

1

Transformer unit with built-in

ignition transformer

2

Electrical angular plug connector

3

Gas connection, may be

connected on either side right and

left with gas test socket

4

Air connection, mounted to

transformer unit

5

Air test socket

6

Igniter tube, mounted to air flange

7

Spacer ring

8

Ignition electrode connection rods

9

Gas tube

10

Ignition electrode connection rods

11

Gas nozzle for natural gas or

propane

12

Mixing chamber

*

The outside diameter will be 50 mm for

tube lengths above 4000 mm and for all

high-grade steel tubes.

Mounting flange

View A

Gas RP1/2

normally left

Air Rp1

Ignition Burner Type ZT0