23

•

the flexiple pipe does not exceed 2000 mm in length (or refer to applicable local regula

-

tions) and does not come into contact with sharp edges, corners or moving parts. Use

a single flexible pipe only; never connect the cooker with more than one flexible pipe.

•

the flexible pipe can easily be inspected along its entire length to check its condition; if it

has an expiry date, it should be replaced before that date.

•

if using a flexible pipe which is not entirely made of metal, make sure that it does not

come into contact with any part of the cooker with a surface temperature of 70°C or

above (or refer to applicable local regulations).

•

the hose is not subject to excessive heat by direct exposure to flue products or by con

-

tact with hot surfaces.

•

the rigid or flexible pipe is replaced if it shows signs of wear or damage.

•

a gas pressure regulator, in compliance with the applicable local regulations, is installed

when connecting to an LPG cylinder.

•

you inform the customer that the cylinder valve or the supply valve immediately by the

appliance should be closed when the cooker is not in use.

•

you inform the customer that the rigid or flexible pipe should not be subjected to corro

-

sion by acidic cleaning agents.

After connecting the cooker to the gas supply, make sure that you

•

check that the connections are correctly sealed using a soapy solution, but never a

naked flame.

•

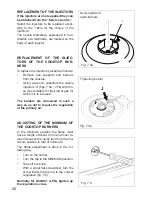

check whether the injectors are correct for the type of gas being used. If not, follow the

instructions under “GAS MAINTENANCE”.

•

replace the sealing washer/s on the slightest sign of deformation or imperfection. The

sealing washer/s is/are the part/s which guarantee/s a good seal in the gas connection.

•

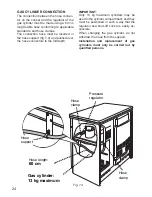

use two spanners when connecting the rigid or flexible pipe (Fig. 7.3).

Gas connection with rigid or flexible pipe

Note: if already fitted on the inlet pipe,

remove the rubber hose holder

1/2” G cylindrical

(ISO 228-1) male

1/2” G cylindrical

(ISO 228-1) male

1/2” G cylindrical

(ISO 228-1) female

1/2” G cylindrical

(ISO 228-1) female

1/2” G cylindrical

(ISO 228-1) female

(#) If not already fitted on the inlet

pipe, it is supplied with the

appliance in a separate kit

Inlet pipe

Manifold male

pipe fitting

Sealing washer (#)

Sealing washer (#)

Brass connector (#)

Flexible pipe

(not supplied)

Rigid pipe

(not supplied)

Fig. 7.3

Содержание EGC 833 series

Страница 14: ...14 A B S Fig 5 4 Fig 5 5 Fig 5 6 S F C Fig 5 3 Fig 5 2...

Страница 30: ...30...

Страница 31: ...31...