Maintenance

54

This procedure should be performed every

500 hours or six months, whichever comes

first.

The hydraulic tank is a vented-type tank. The

breather cap has an internal air filter that can

become clogged or, over time, can deteriorate.

If the breather cap is faulty or improperly

installed, impurities can enter the hydraulic

system which may cause component damage.

Extremely dirty conditions may require that the

cap be inspected more often.

1. Remove and discard the hydraulic tank

breather cap.

2. Install the new cap onto the tank.

Checklist D

D-1

Check the Scissor Arm Wear Pads

This procedure should be performed every

1000 hours or annually, whichever comes first.

Maintaining the condition of the scissor arm

wear pads is essential to safe machine

operation. Continued use of worn-out wear

pads may result in component damage and

unsafe operating conditions.

Perform this procedure with the machine on a

firm, level surface that is free of obstructions.

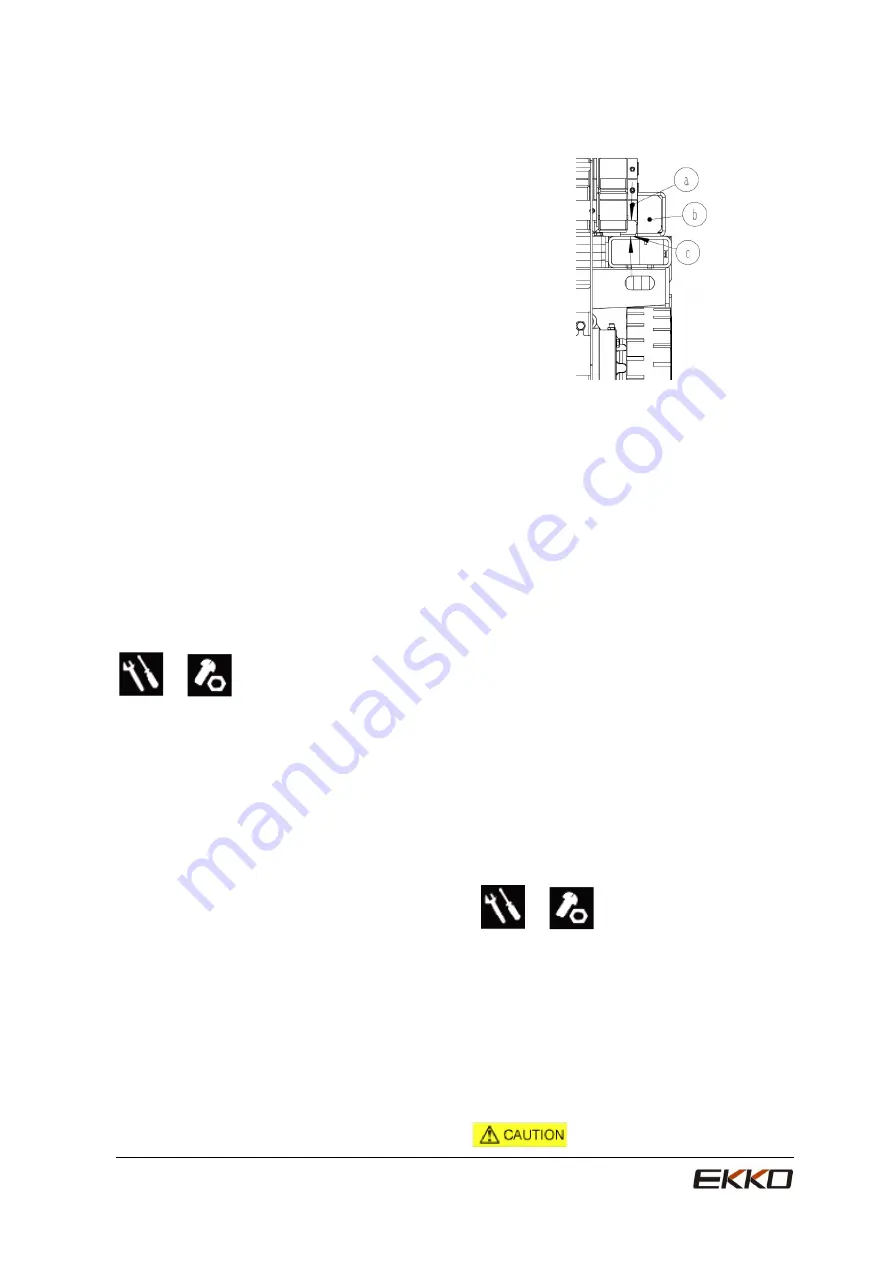

1. Measure the distance between the

number one inner arm cross tube and the

chassis deck at the ground controls side of

the non-steer end of the machine.

a. inner arm cross tube

b. wear pad

c.

chassis deck

⊙

Result: The measurement is not less than x

mm. (ZS07

:

x=34.5

,

ZS12

:

x=38) Refer to

Step2.

¤

Result: The measurement is less than x

mm. Replace the Scissor Arm Wear Pads

2. Measure the distance between the

number one inner arm cross tube and the

chassis deck at the battery pack side of

the non-steer end of the machine.

⊙

Result: The measurement is not less than x

mm. Refer to Step 3.

¤

Result: The measurement is less than x mm.

Replace the Scissor Arm Wear Pads

3. Apply a thin layer of dry film lubricant to

the area of the chassis where the scissor

arm wear pads make contact.

D-2

Replace the Hydraulic Tank Return

Filter Element

This procedure should be performed every

1000 hours or annually, whichever comes first.

Replacement of the hydraulic tank return filter

is essential for good machine performance

and service life. A dirty or clogged filter may

cause the machine to perform poorly and

continued use may cause component damage.

Extremely dirty conditions may require that the

filter be replaced more often.

Scalding danger

Содержание ES100E

Страница 5: ...Decals 3 ...

Страница 7: ...Decals 5 ...

Страница 9: ...Decals 7 ...

Страница 59: ...Electrical Schematic Diagram 57 ES40E ...

Страница 60: ...Electrical Schematic Diagram 58 ES60E ES80E ES100E ES120E ...

Страница 62: ...Hydraulic Schematic Diagram 60 ES80E Y7 Y7 G1 4 19 Y1 Y1 Y2 Y2 Y3 Y3 Y4 Y4 Y5 Y5 Y6 Y6 ...

Страница 63: ...Hydraulic Schematic Diagram 61 ES100E ES120E Y7 Y7 G1 4 19 Y1 Y1 Y2 Y2 Y3 Y3 Y4 Y4 Y5 Y5 Y6 Y6 ...

Страница 64: ...Hydraulic Schematic Diagram 62 Maintenance Record Date Note ...

Страница 65: ......