Mechanical Operations and Maintenance Manual for Industrial Robot ER10-1600

21

capacity should meet the relevant quality specifications, the thickness of the concrete should not be less

than the filling depth of the chemical bolts, and the effective range should completely cover the fixed

bottom plate to ensure the safety and reliability of the bottom plate installation.

The concrete strength grade C20/C25 is implemented with reference to the following specifications:

GB50010-2010 "Specification for Design of Concrete Structures" and GB/T50081-2002 "Test Methods for

Mechanical Properties of Ordinary Concrete"

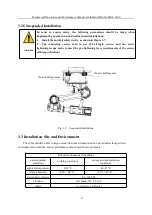

Table 3-1 Parts List Required for Robot Fixation

Name

Specification

Number

bottom plate

thickness

≥

30mm

one

reference area

(

600mm

×

600mm

)

chemical bolt

group

above M16, strength grade ≥ 4.8

eight

fixing screws

M16

×

45, strength grade 12.9

four

taper pins with

internal thread

M12x45

two

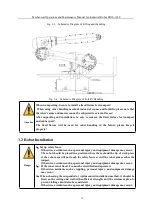

When installing on the ground, first fix the bottom plate on the ground. We recommend that the

thickness of the bottom plate should be more than 30mm. Use 8 chemical bolts of M16 or more to fix the

bottom plate on the ground. The base of the robot is firmly fixed on the bottom plate with M16 hexagon

socket screws of strength grade 12.9 through the four mounting holes (the length of the screw must ensure

that the screw thread length reaches 1.5 times the nominal diameter of the thread). If there is no loosening

during operation, please fully fix and prevent loosening as shown in Figure 3-6 "Robot Installation

Example".

chemical bolt groups

(specification requires more than M16*200)

the robot base

the thickness of bottom plate is 30 mm

foundation