36

11.3.7- Annual Maintanence Reminder

:

This mode reminds user that “annual

maintanence time is very soon”. When this mode is active, only "ASE" is displayed on

screen and boiler continues to meet heating requests. Electrical connection of boiler

must be always connected to mains, otherwise function will not work properly. When

you see "ASE" on screen, please check your boiler start up date and contact with gas

safe engineer if annual maintanence period is arrived. If maintance of the boiler is

done

before “ASE” appears on screen, you can skip it by pressing “R” button.

11.3.8- Anti-Frost Mode:

During the winter season, when the installation water temperature falls below

6 ° C, the anti-freeze function is activated and the boiler continues to operate until the water output of

installation rises to 15 ° C. In order for anti-freeze function to be activated, the following conditions must be

checked and ensured by the customer.

The power supply of the boiler must be switched on.

The gas valve and radiator valves must be open.

Water pressure of system should be at appropriate level.

The anti-freeze function helps protect your boiler, it does not protect your installation.

If the boiler will not be operated for a while in places where there is risk of freezing, then it is necessary

to drain the water or to use an anti-freeze agent

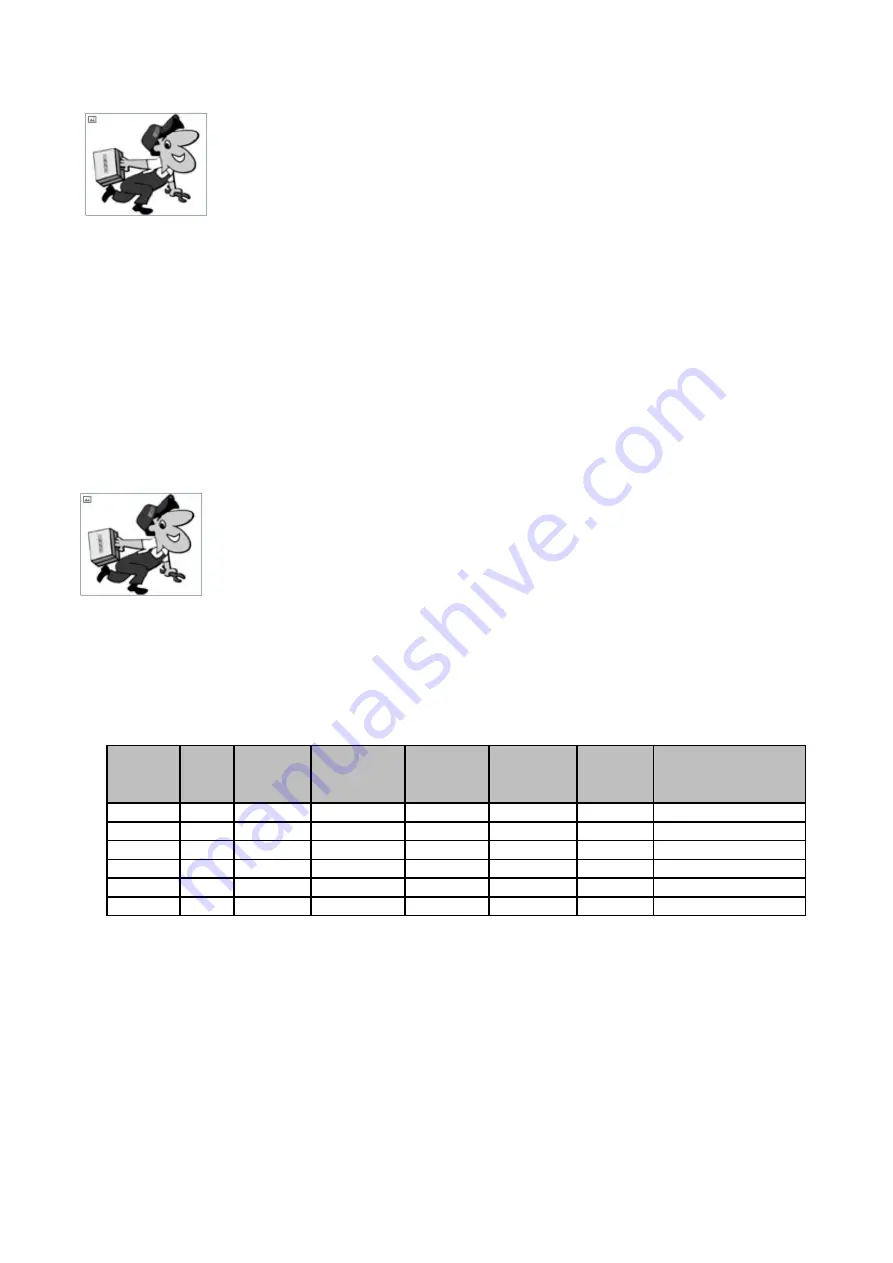

12-GAS CONVERSION

Gas conversion operation from natural gas to LPG must be performed by gas

safe engineer. If the user requests gas transformation after purchase of the

boiler, it is subject to a fee

.

For the gas conversion process, a conversion kit is required.The conversion kit includes

1 gas orifice, 1 gasket and 1 gas conversion label. Procedure for gas conversion is;

Installation of parts in the conversion kit

Gas adjustment

Parameter change (P01: 0 for natural gas, P01:1 for LPG)

GAS SETTING CHART

Capacity

Gas

Type

Gas

Orifice

Diameter

Orifice

Diameter

Code

P01

Parameter

Max. Fan

Speed

(rpm)

Min. Fan

Speed

(rpm)

Front Cover Closed

CO2

(Max/Min) (%)

24 kW

NG

7.65±0.05 7006990320

0

6250

1850

9.5±0.2 / 8.9±0.2

24 kW

LPG

6.5±0.05 7006990685

1

6100

1850

10.6±0.2 / 9.9±0.2

30 kW

NG

7.9±0.05 7006990688

0

6900

2100

9.5±0.2 / 8.9±0.2

30 kW

LPG

7.1±0.05 7006990691

1

6850

2100

10.6±0.2 / 9.9±0.2

35 kW

NG

8.1±0.05 7006990690

0

7600

2300

9.5±0.2 / 8.9±0.2

35 kW

LPG

7,1±0.05 7006990694

1

7600

2300

10.6±0.2 / 9.9±0.2

Table 10.Gas Setting Table